Steelmaking Vacuum Converter

Steelmaking Vacuum Converter

Product Description

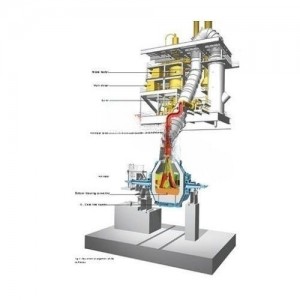

Steelmaking vacuum converter, generally speaking, refers to tilting cylindrical oxygen blowing steel vessel.

It is a type of steelmaking furnace. The furnace body is cylindrical, which is supported on a horizontal shaft frame and can rotate. It's also used to make copper.

Converter steelmaking takes molten iron, scrap steel and ferroalloy as main raw materials, does not rely on external energy, but relies on physical heat of molten iron itself and heat generated by chemical reaction between components of molten iron to complete steelmaking process in converter. converter is divided into acid and basic according to refractory materials, top blowing, bottom blowing and side blowing according to gas blowing into the furnace, and air converter and oxygen converter according to gas type. Basic oxygen top blowing converter and top bottom combined blowing converter are the most commonly used steelmaking equipment because of its high production speed, large output, high output per furnace, low cost and low investment. Converter is mainly used to produce carbon steel, alloy steel, copper and nickel smelting.

Technical and economic indexes of 150~300t steelmaking vacuum converter are show as following:

| Smelting time | 30min |

| Oxygen blowing | 16~20min |

| Oxygen consumption | 48~58m3/t |

| Steel consumption | 1060~1150kg/t |

| Scrapes consumption | 15%~30% |

| Lime consumption | 30-70kg/t |

| Fluorite consumption | 0.0~3.0kg/t |

| Iron ore consumption | 30~50kg/t |

| Furnace lining consumption | 3~7kg/t |

| Power consumption | 9~12kw·h/t |

| Annual output | 10000~15000MT |