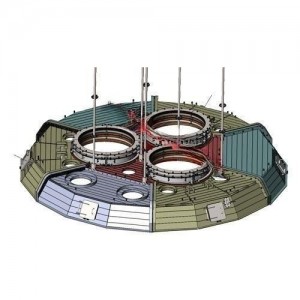

Silicon Metal Furnace

Silicon Metal Furnace

Product Description

Silicon metal furnace is to use submerged arc furnace to produce silicon metals, and the furnace is normally semi closed type.

Silica quartz and carbonaceous reductant are major raw materials for silicon metal smelting. Most Silicon metal furnaces are semi closed. Due to power costive of silicon metal production, power costs is the essential for silicon metal smelting production. High purity silica quartz is necessary for silicon metal production, and its chemical composition show as following:

| SiO2 | Fe2O3 | Al2O3 | CaO |

| >99.00% | <0.057% | <0.14% | <0.03% |

According to usage of silicon metal, it is classified as metallurgical and chemical purity with details of each purity as following

| Grade

|

Chemical Compositions | ||||

| Si (%)

|

Impurity Content (%) | ||||

| Fe | Al | Ca | P | ||

| 1515 | >99.6% | ≤0.15 | / | ≤0.015 | ≤0.004% |

| 2202 | >99.5% | ≤0.2 | ≤0.2 | ≤0.02 | ≤0.004% |

| 2203 | >99.5% | ≤0.2 | ≤0.2 | ≤0.03 | ≤0.004% |

| 2503 | >99.5% | ≤0.2 | — | ≤0.03 | ≤0.004% |

| 3103 | >99.4% | ≤0.3 | ≤0.1 | ≤0.03 | ≤0.005% |

| 3303 | >99.3% | ≤0.3 | ≤0.3 | ≤0.03 | ≤0.005% |

| 411 | >99.2% | ≤0.4 | 0.04-0.08 | ≤0.1 | / |

| 421 | >99.2 % | ≤0.4 | 0.1-0.15 | ≤0.1 | / |

| 441 | >99.0 % | ≤0.4 | ≤0.4 | ≤0.1 | / |

| 553 | >98.5 % | ≤0.5 | ≤0.5 | ≤0.3 | / |

Write your message here and send it to us