Silicon Manganese Furnace

Silicon Manganese Furnace

Product Description

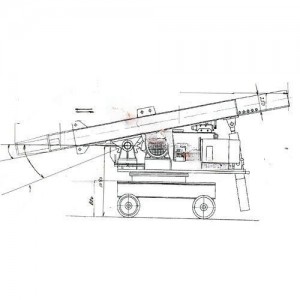

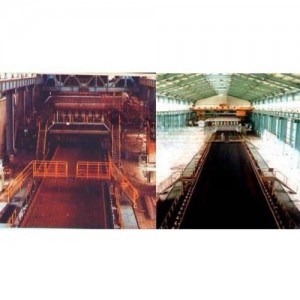

Silicon manganese furnace is much similar to ferrosilicon furnace.

Silicon manganese is a chemical compound made by mixing natural silicon with manganese, an element found naturally in the earth. When combined, these elements can be used to produce a number of specialty steel alloys. This compounds enhances the natural properties of steel, giving it increased strength and function, as well as improved aesthetic appeal. This means that these alloys can be used in applications beyond those associated with standard steel products. Silicon manganese may also be known as ferro silico manganese or abbreviated as SiMn.

This compound may be used alone, or combined with other substances to create various alloys. The ratio of silicon to manganese can also be adjusted to give steel the desired properties. Standard silicon manganese steel alloys contain 14% to 16% silicon, and as much as 68% manganese. They also include small amounts of carbon, which is required for the steel to undergo a chemical reactions with these compounds. In stainless or specialty steel products, the silicon content can be as high as 30%.

To create steel alloys with silicon manganese, manufacturers must first harvest these materials from the earth using traditional mining techniques. They are combined in precise ratios, resulting in a liquid chemical compound. As the iron ore and carbon are melted in a furnace, the compound is added to the molten mixture. A chemical reaction takes place when these components meet, which deoxidizes the iron, resulting in a strong, rust-resistant steel alloy. The silicon manganese naturally separates as a liquid, making it easy for users to remove this material from the furnace.

These elements offer a number of advantages when used in steel production. Each of these substances acts as a powerful deoxidizer on its own. By combining the two, manufacturers can maximize these deoxidization properties to enhance the steel's durability. Alloys made using this compound offer a high level of resistance against rust, making them suitable for outdoor or moisture-prone applications. They also resist corrosion, and can be used around certain types of chemicals or in coastal areas.

The addition of silicon manganese to steel also results in a purer, cleaner steel alloy. These chemicals draw naturally-occurring elements like phosphorous out of the steel. This means fewer impurities and a better quality product. Compared to traditional steel, alloys made using this technique take longer and cost more to produce. This means higher prices and longer lead times for builders and other end users.

Silicon manganese furnace production is similar to high carbon ferromanganese, which use coke as major reductant. In order to smelting different grade silicon manganese alloys, quality requirements of manganese ores are various, which show as following:

| Grade | Manganese ore quality | ||

| Mn%≥ | Mn/Fe≥ | P/Mn≤ | |

| FeMn60Si25

FeMn63Si22 FeMn65Si20 FeMn65Si17 FeMn65Si14 |

32.0

32.0 32.0 32.0 32.0 |

8.0

6.8 7.7 6.5 5.5 |

0.001-0.002

0.001-0.002 0.001-0.002 0.001-0.002 0.001-0.002 |

Silicon manganese furnace cannot be used to produce high carbon ferromanganese unless in small furnace as 6000KVA, otherwise, risks of furnace lining damage will be happen.