Refractory Lining In Furnace

Refractory Lining In Furnace

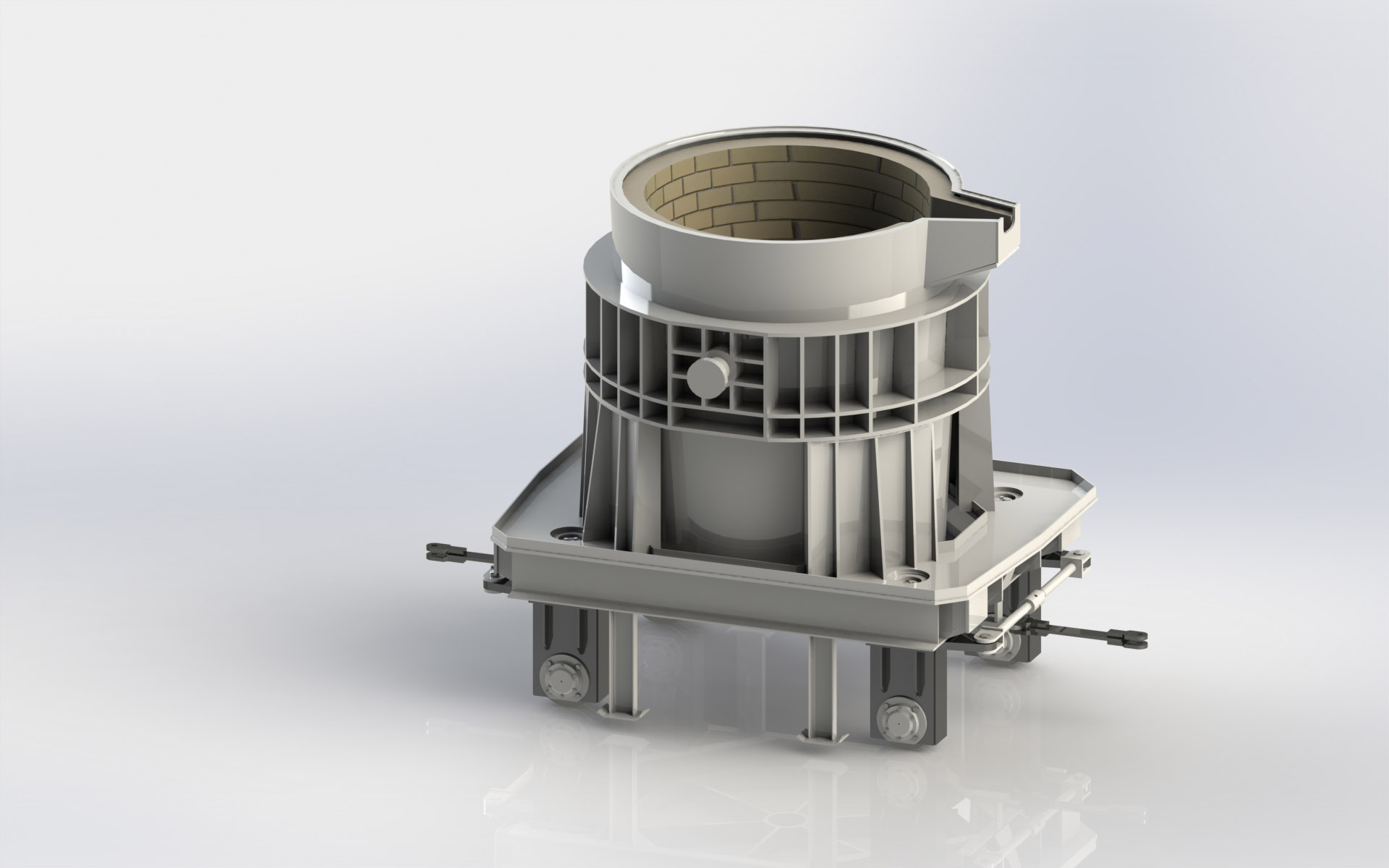

Product Description

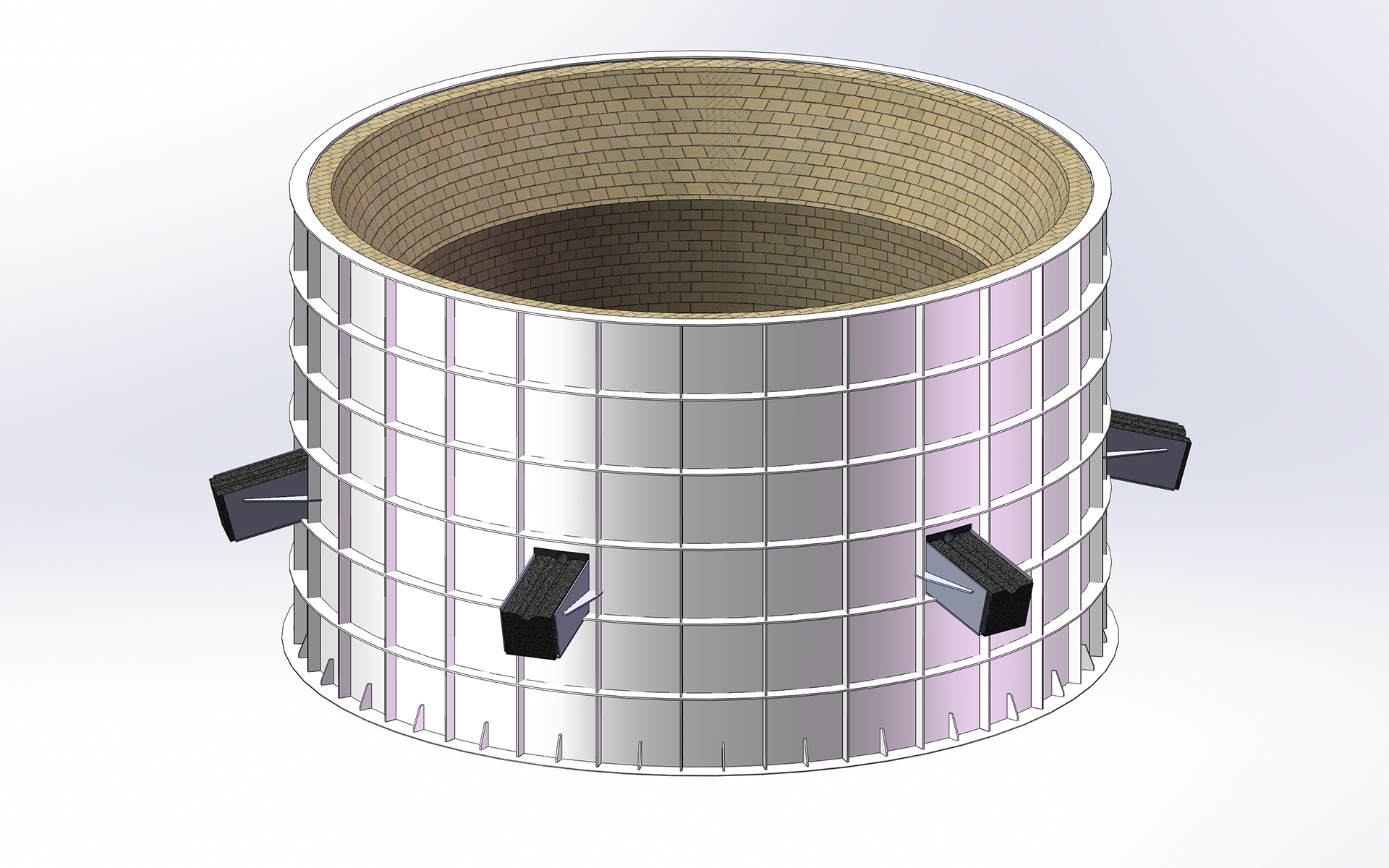

Refractory Lining In Furnace refers to the building materials constructed with different refractories and bricks in the furnace. It is basically a protective layer installed in the furnace to protect the steel structure from high temperature. Because the smelting process is in the complex environment of high temperature, corrosion and heat loss, the lining damage increases the energy consumption and production cost. Therefore, the optimization of lining structure is an important direction of submerged arc furnace energy saving.

Advantages

The Refractory Lining In Furnace has good thermal conductivity, electrical conductivity and excellent resistance to high temperature, wear resistance and alkali resistance. Our Refractory Lining In Furnace mainly includes carbon brick, magnesia brick and magnesia ramming material. They are widely used in incinerator, nonferrous metal furnace and other industrial furnaces. We can also customize the products according to customer needs.

Parts Drawing

Copper Pipe Row

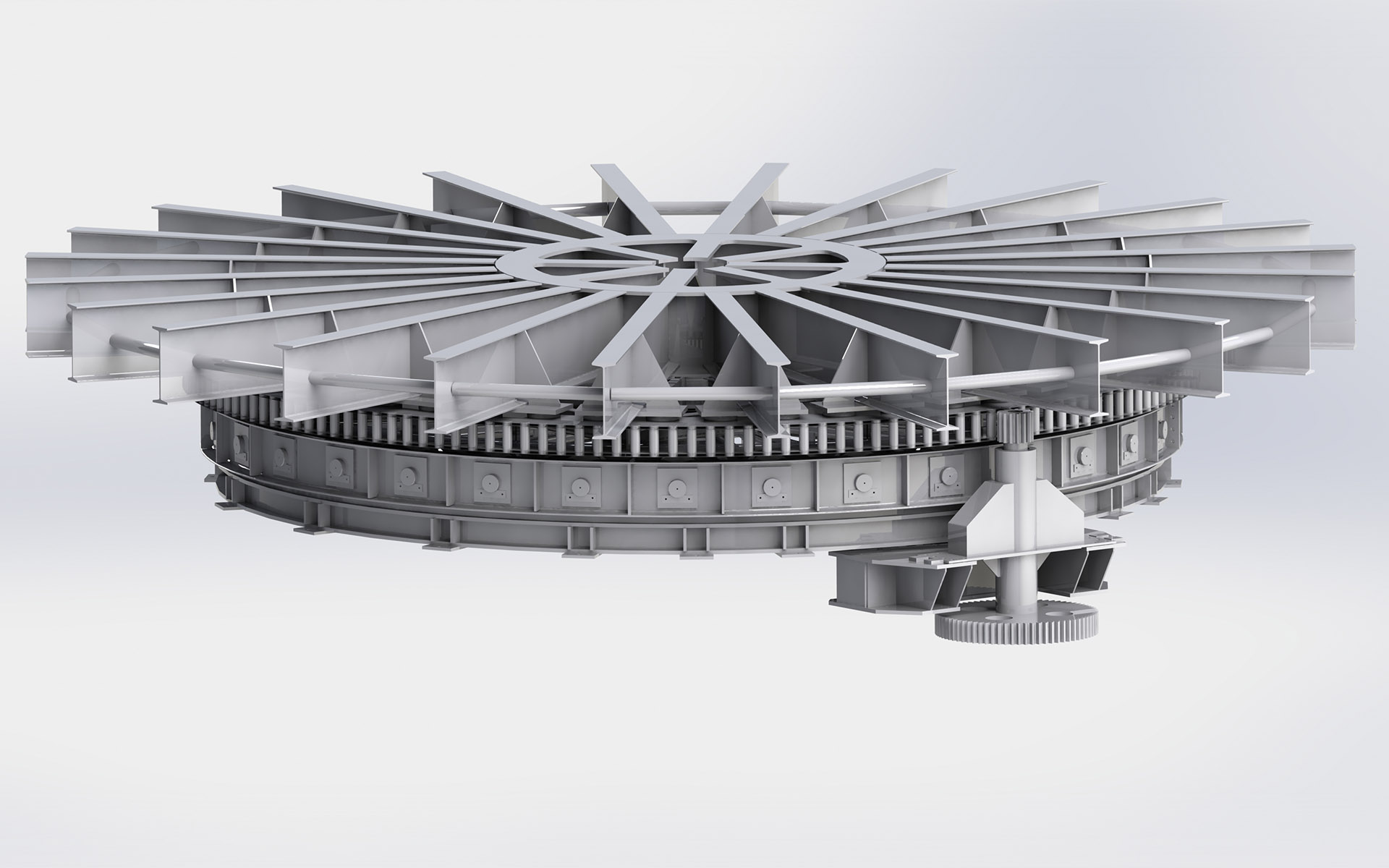

Furnace Rotating system

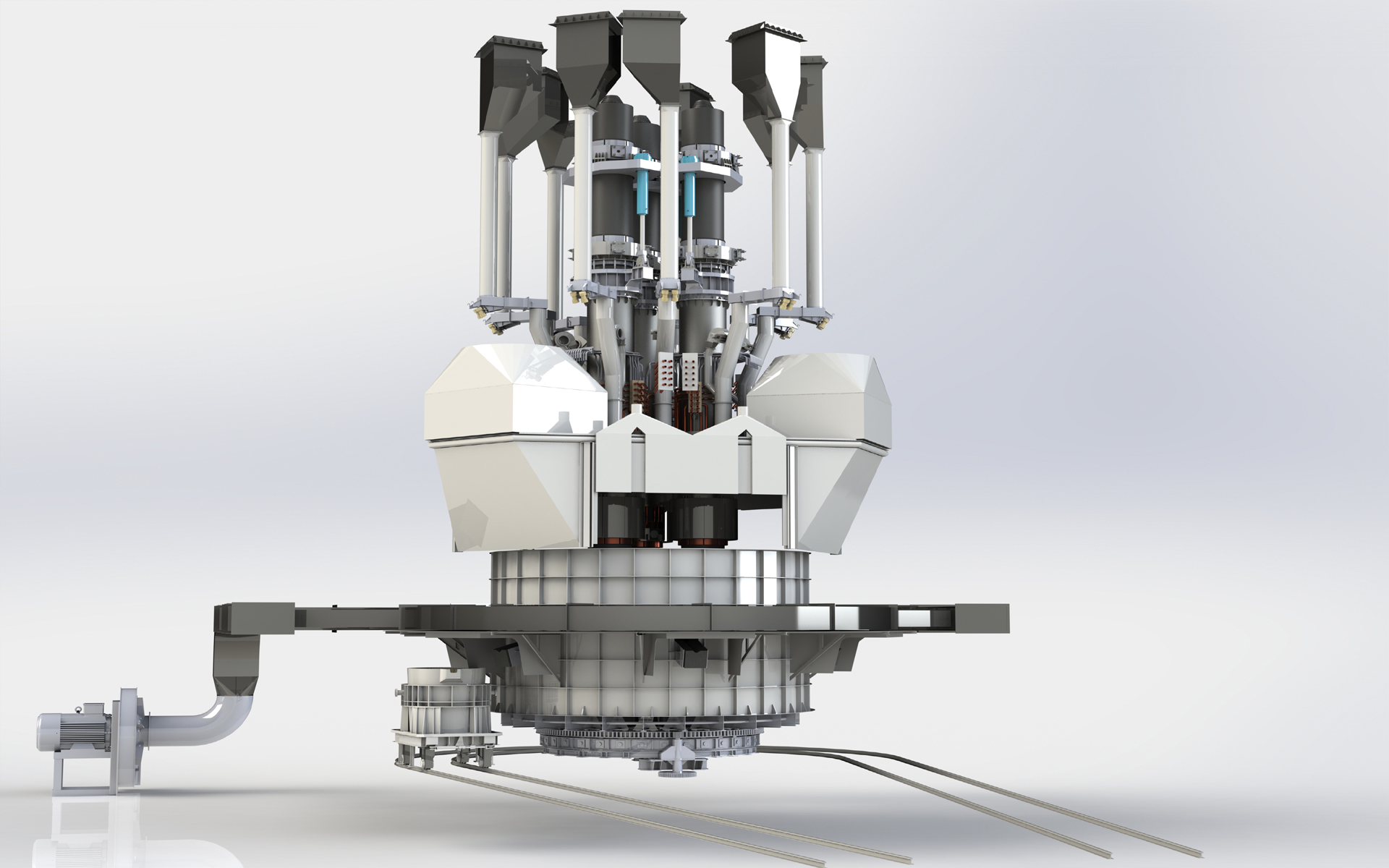

Furnace Assembly

Furnace Shell

Upholding Brake

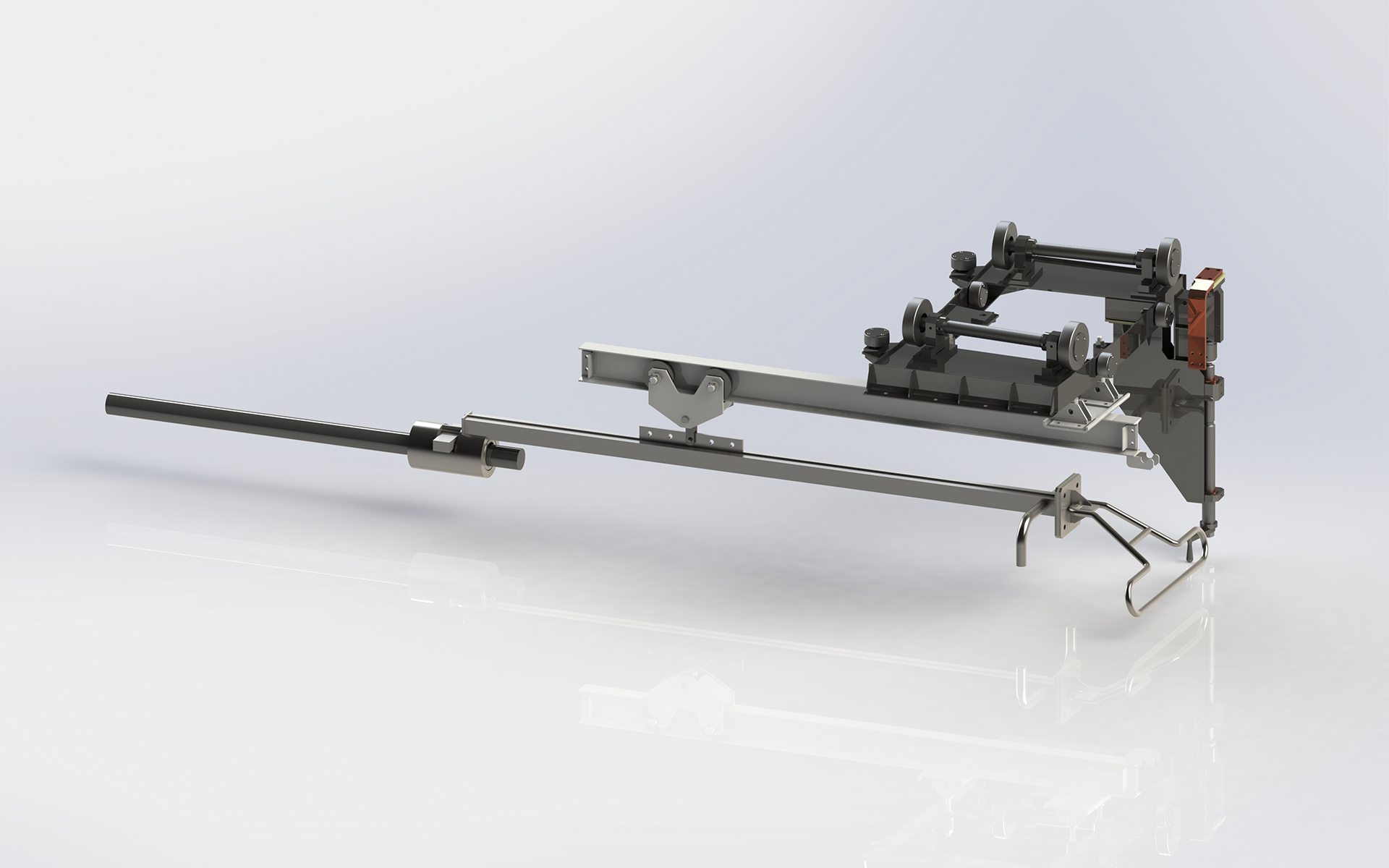

Moveable Arc Burner

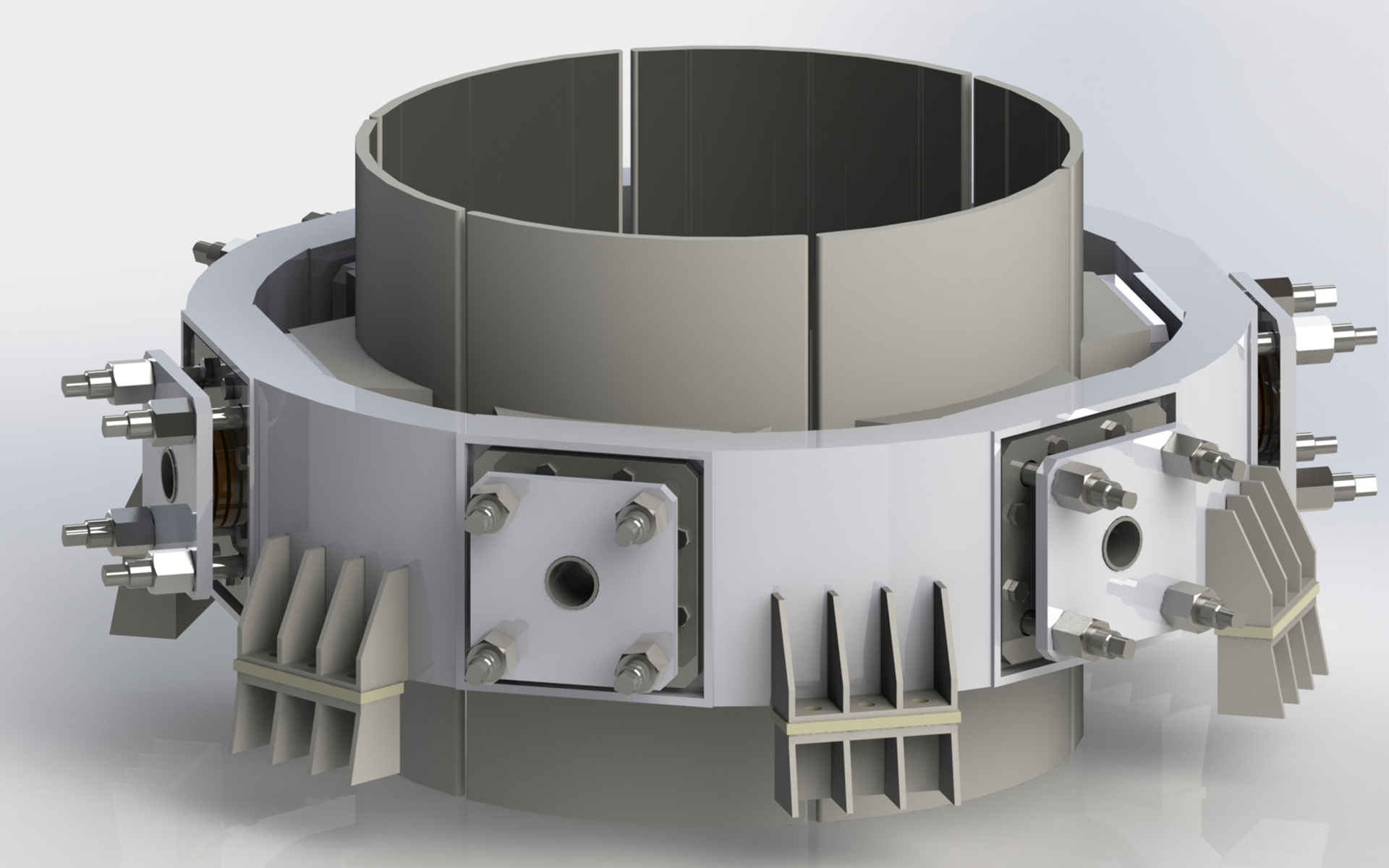

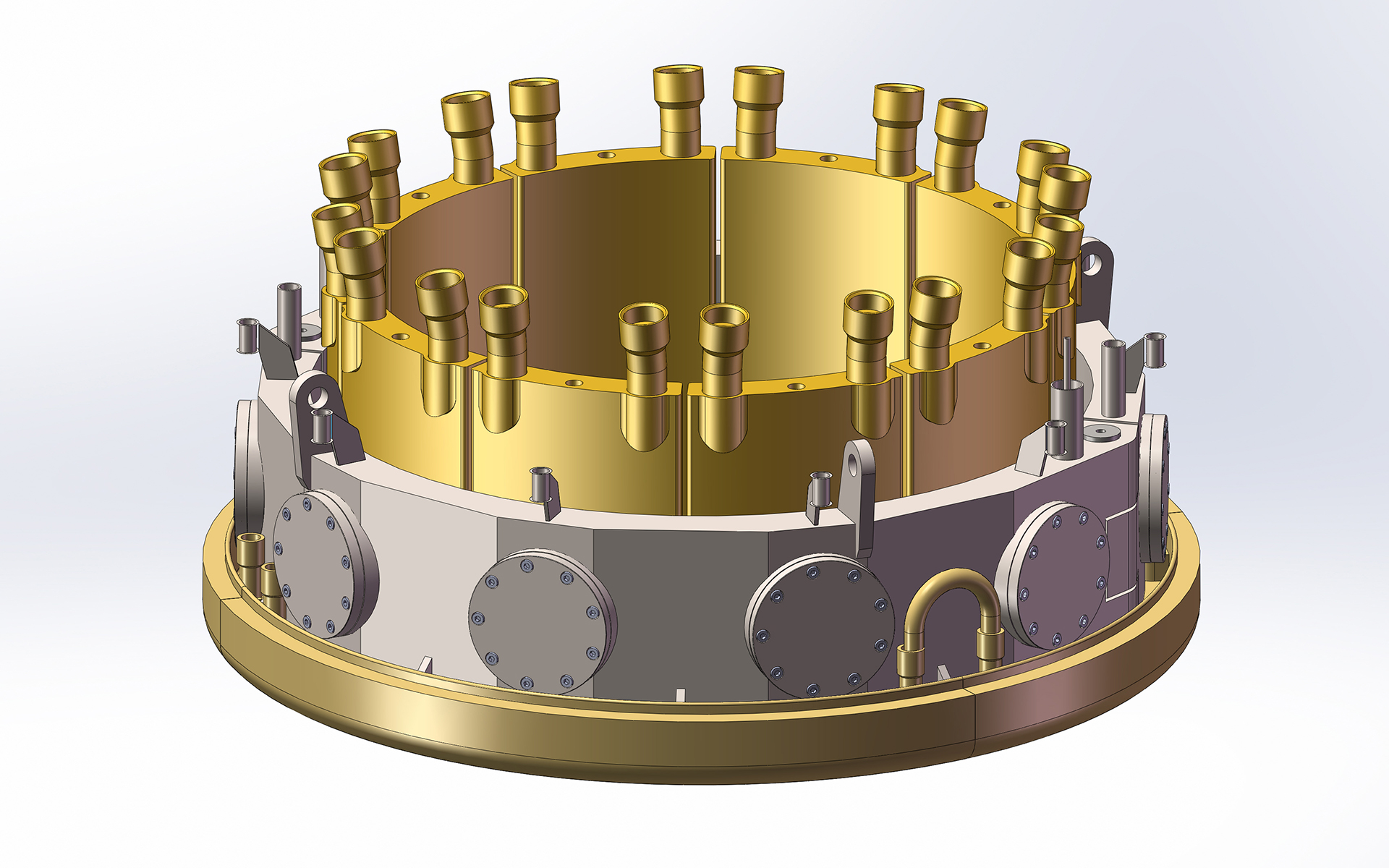

Pressure Ring

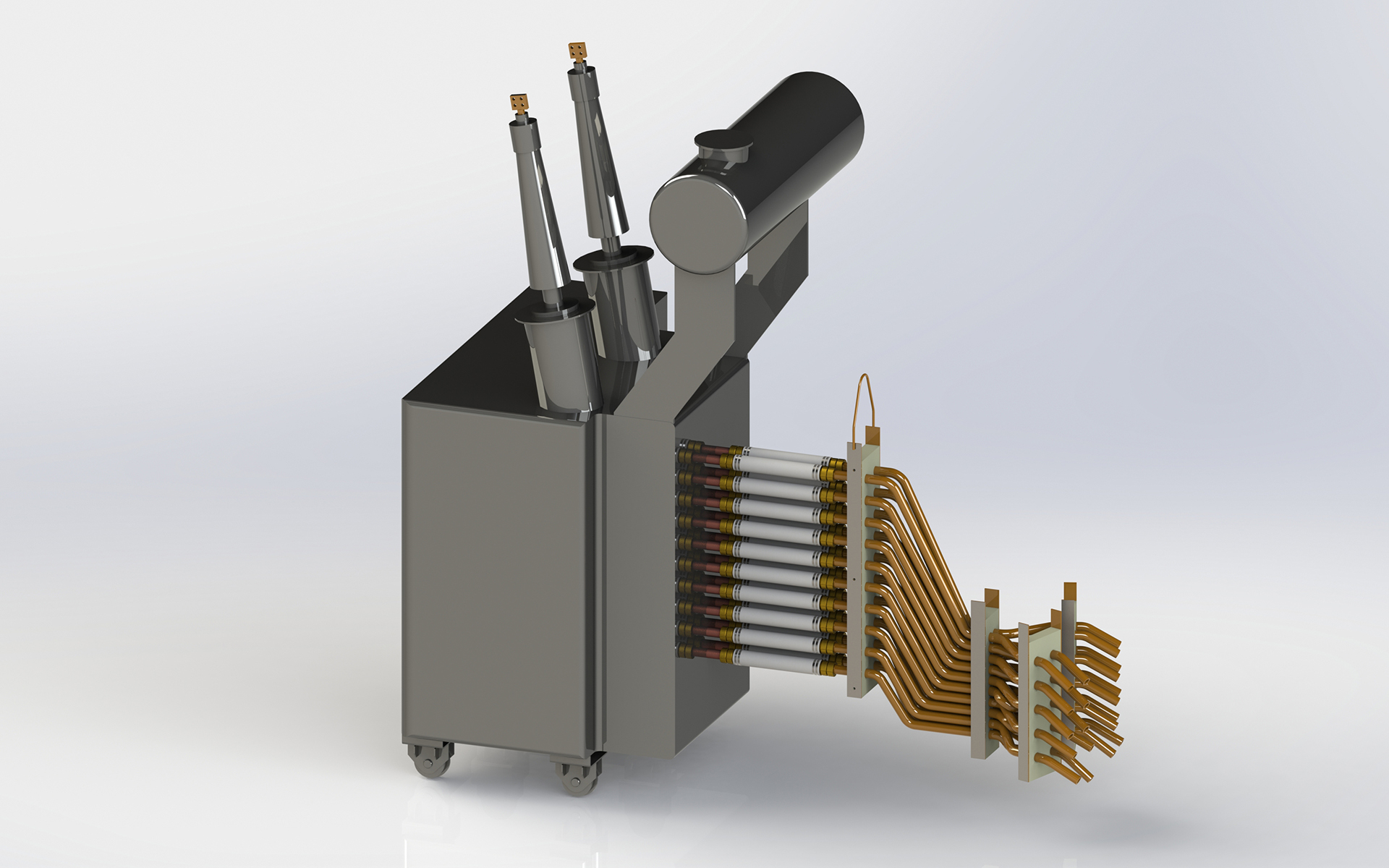

Short Net System

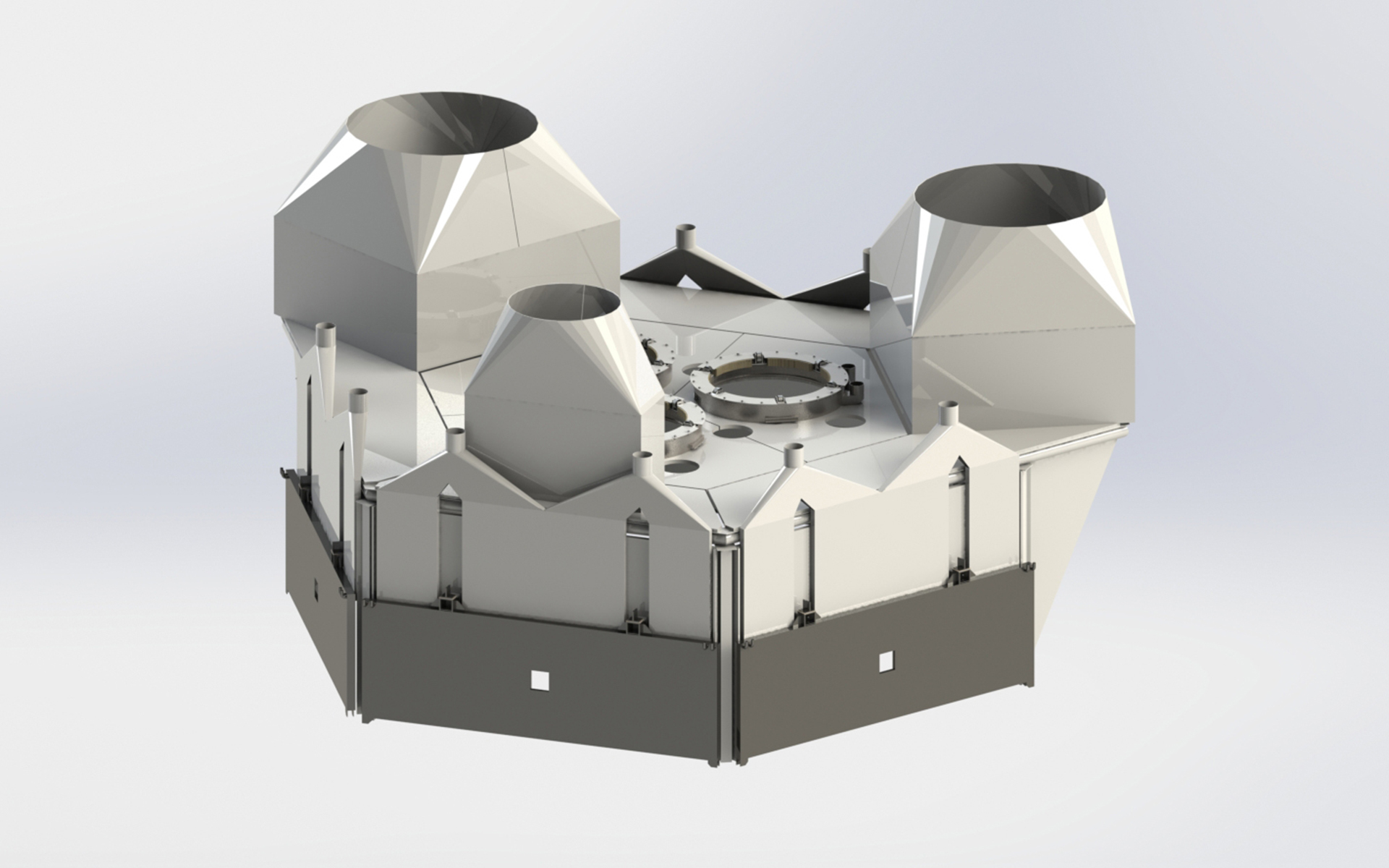

Smoke Hood