Production of Pig Iron In Blast Furnace

Production of Pig Iron In Blast Furnace

Product Description

Production of pig iron in blast furnace here refers to blast furnace with capacity smaller than 500m3 for pig iron production.

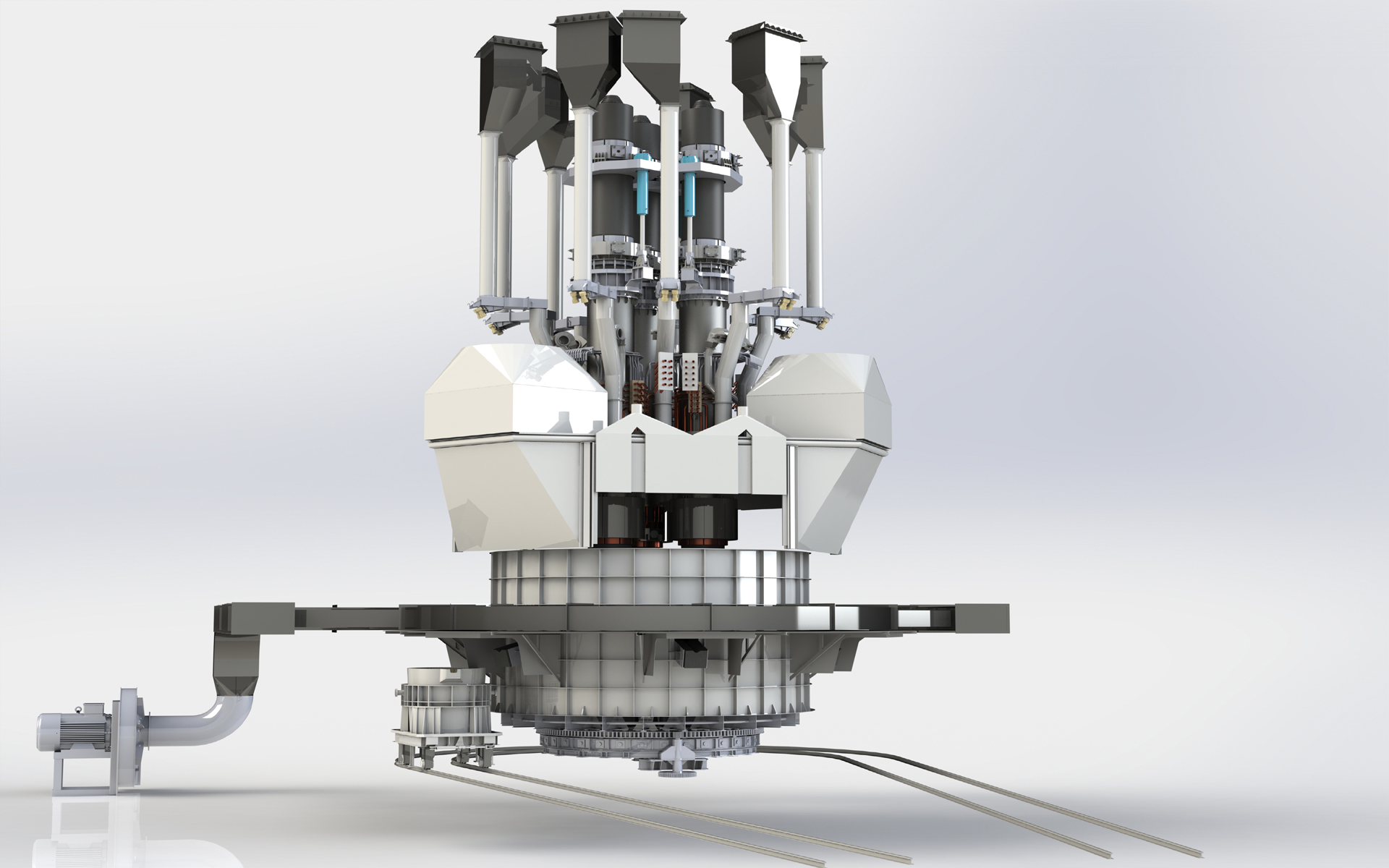

Mini Blast furnace iron making process is formed of blast bunker system, furnace body system, gas system, hot air system, coal injection system, slag iron disposal system, water system, iron casting system and so on.

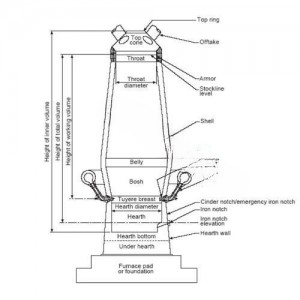

Continuous production of liquid pig iron by coke, iron ore (natural rich lump ore, sinter and pellet) and flux (limestone and dolomite) in a vertical reactor blast furnace is described. It is an important part of modern steel production. Modern blast furnace ironmaking is reformed and developed by ancient shaft furnace ironmaking method. Although many ironmaking methods have been developed in the world, blast furnace ironmaking is still the major method of modern ironmaking because of its relatively simple process, large output, high labor productivity and low energy consumption. Its output accounts for more than 95% of the total output of pig iron in the world.

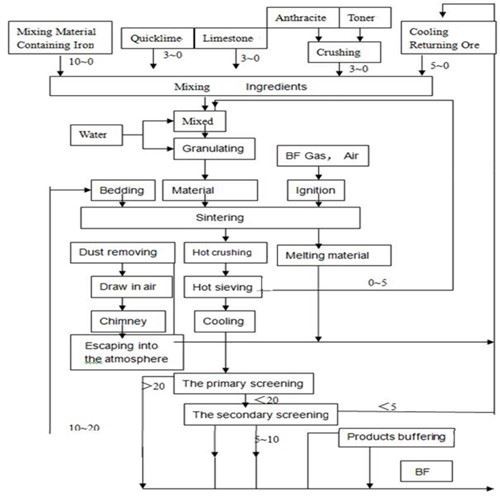

Production process of iron making by mini blast furnace show as following picture:

Here is a typical technical parameters of 230m3 for example as following:

| No. | Name | Unit | Numerical |

| 1 | volume V | m3 | 230 |

| 2 | diameter of hearth d | Mm | 4200 |

| 3 | diameter of furnace bosh D | Mm | 5100 |

| 4 | diameter of furnace throat d1 | Mm | 3200 |

| 5 | thickness of iron layer h0 | Mm | 600 |

| 6 | height of tuyere hf | Mm | 2300 |

| 7 | height of hearth h1 | Mm | 2600 |

| 8 | height of belly h2 | Mm | 2600 |

| 9 | height of furnace bosh h3 | Mm | 1500 |

| 10 | height of shaft h4 | Mm | 8200 |

| 11 | belly angle | 81.86 | |

| 12 | shaft angle | 84.29 | |

| 13 | height of furnace throat h5 | Mm | 1500 |

| 14 | effective height Hu | Mm | 16500 |

| 15 | Hu/D | 3.24 | |

| 16 | tuyere | Piece | 12 |

| 17 | tap hole | Piece | 1 |

| 18 | slag hole | Piece | 1 |

Parts Drawing

Copper Pipe Row

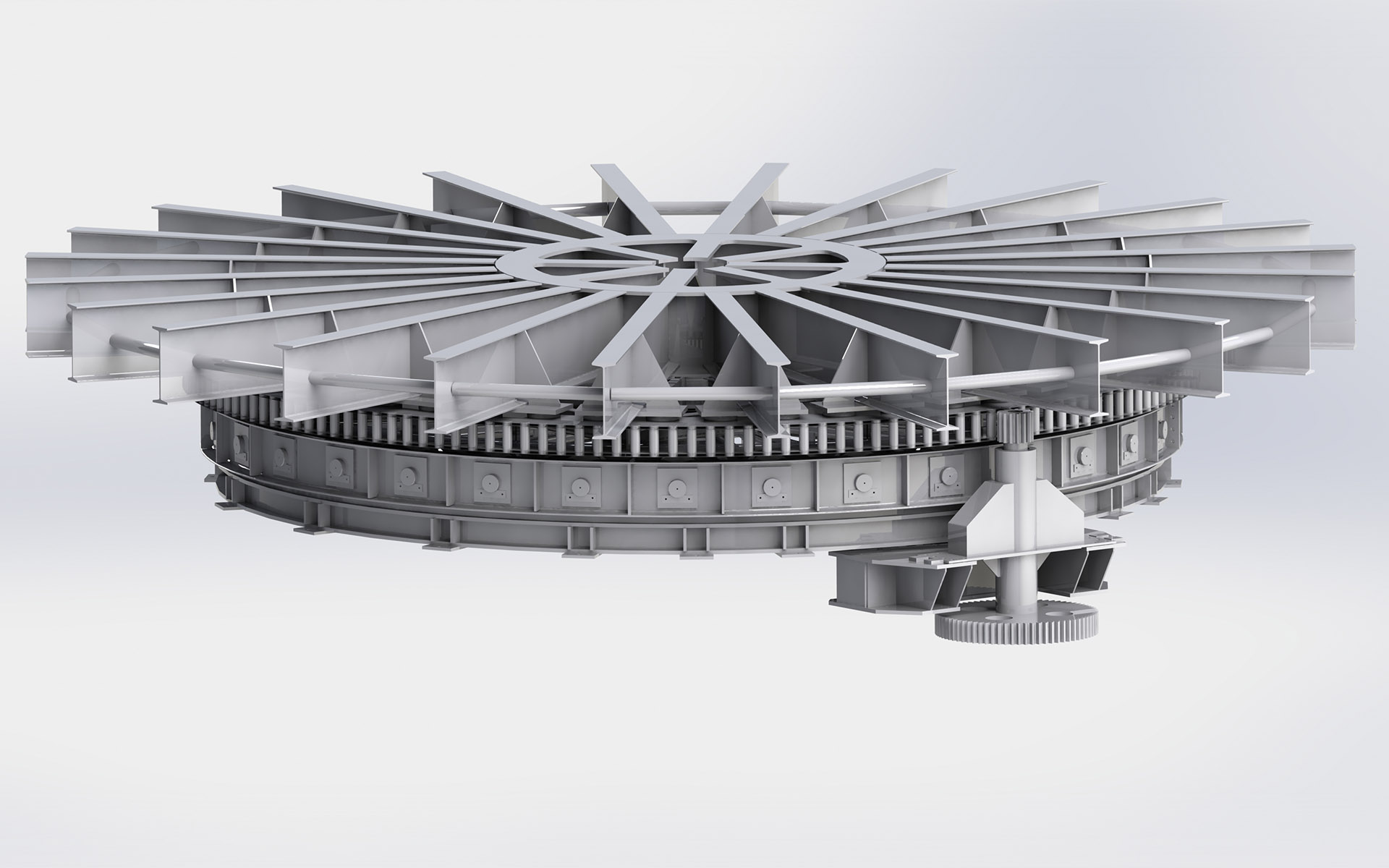

Furnace Rotating system

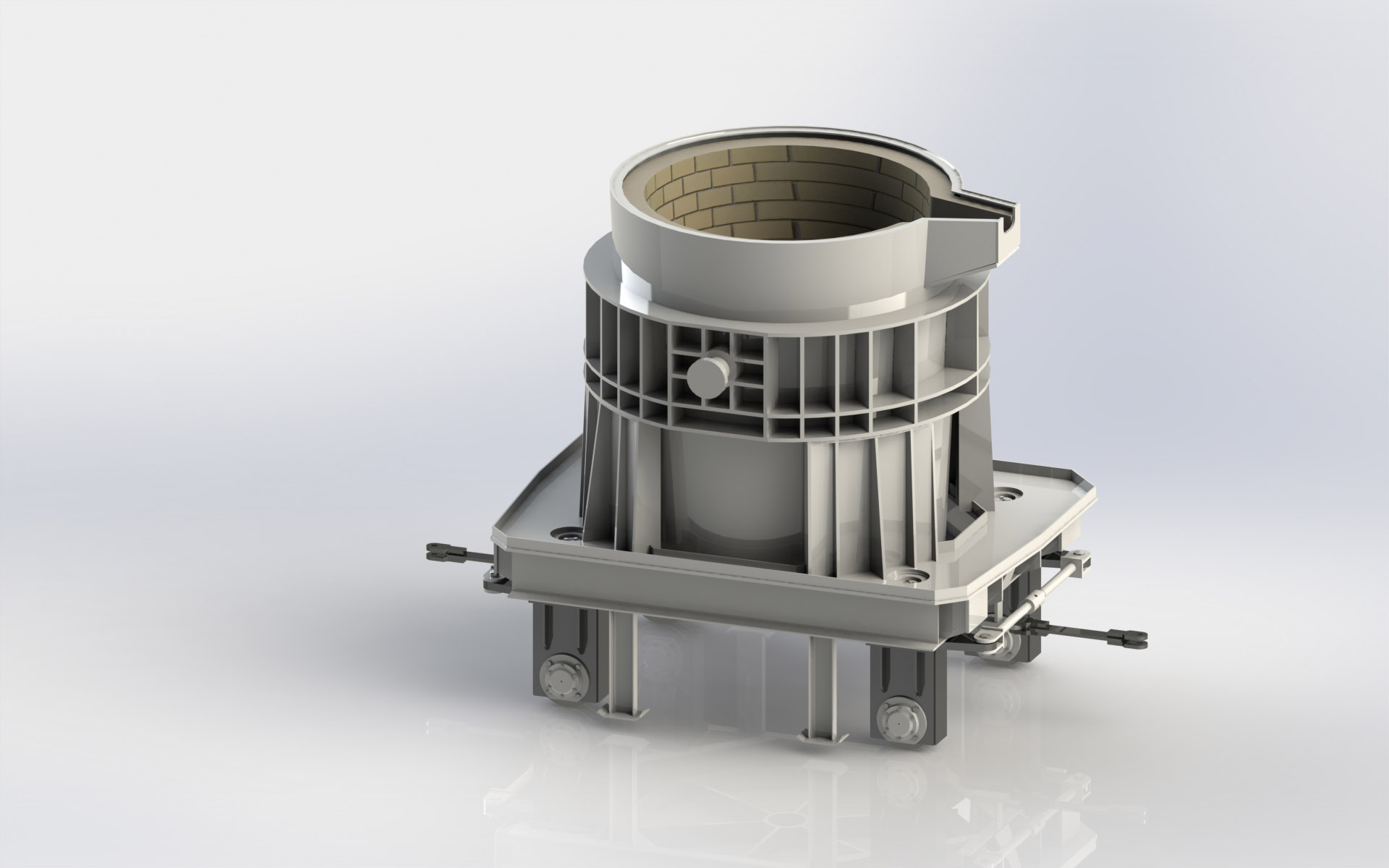

Furnace Assembly

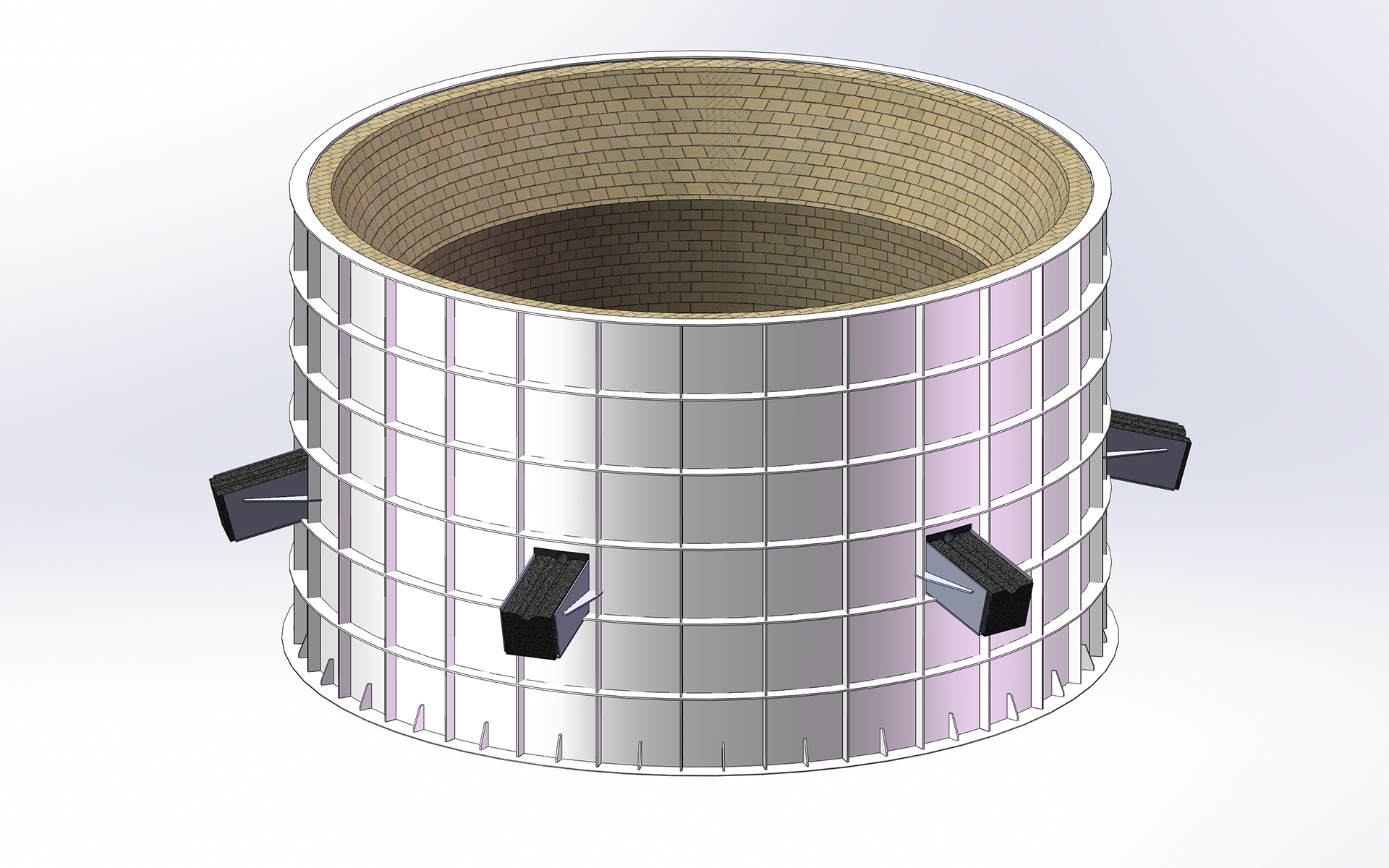

Furnace Shell

Upholding Brake

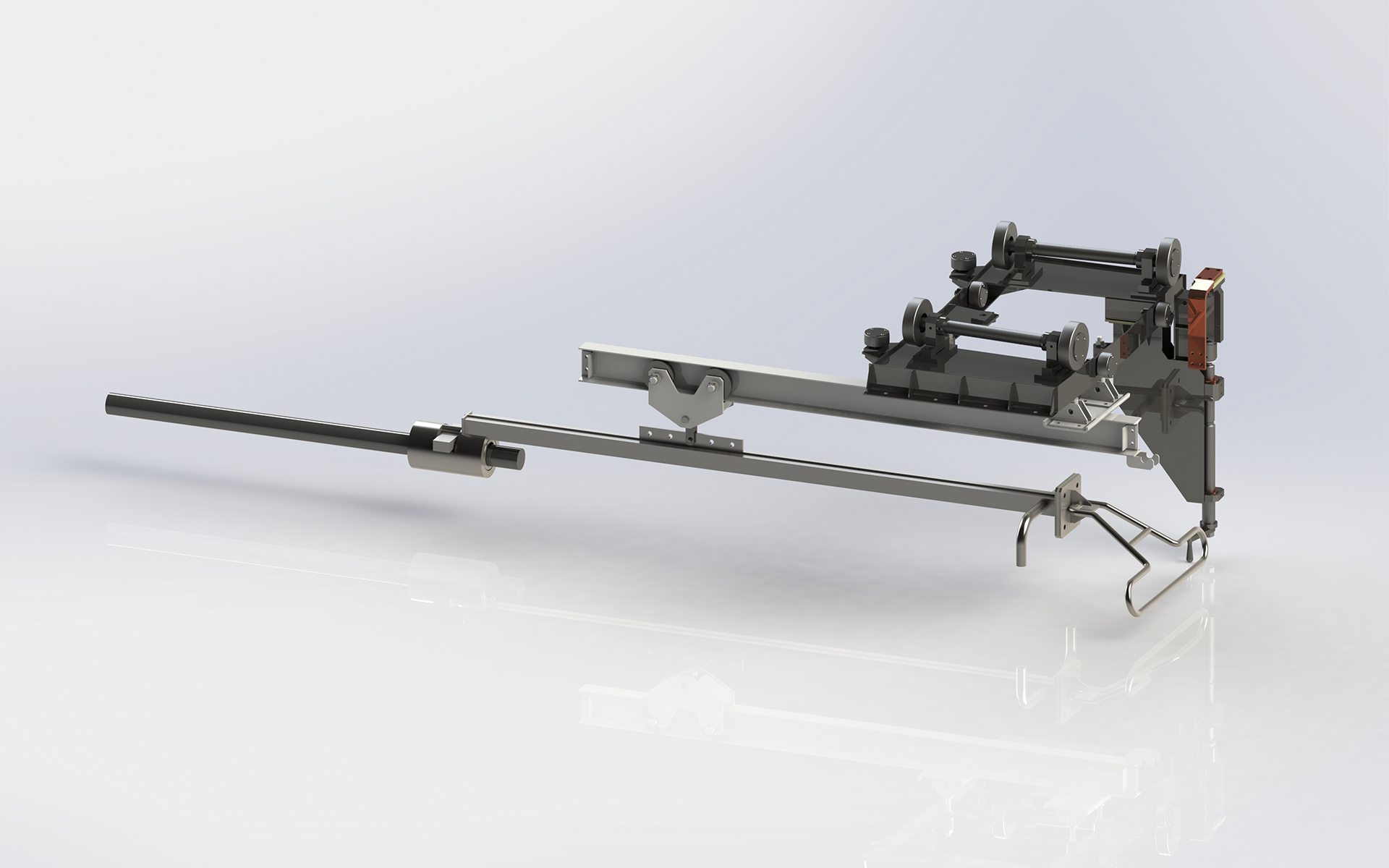

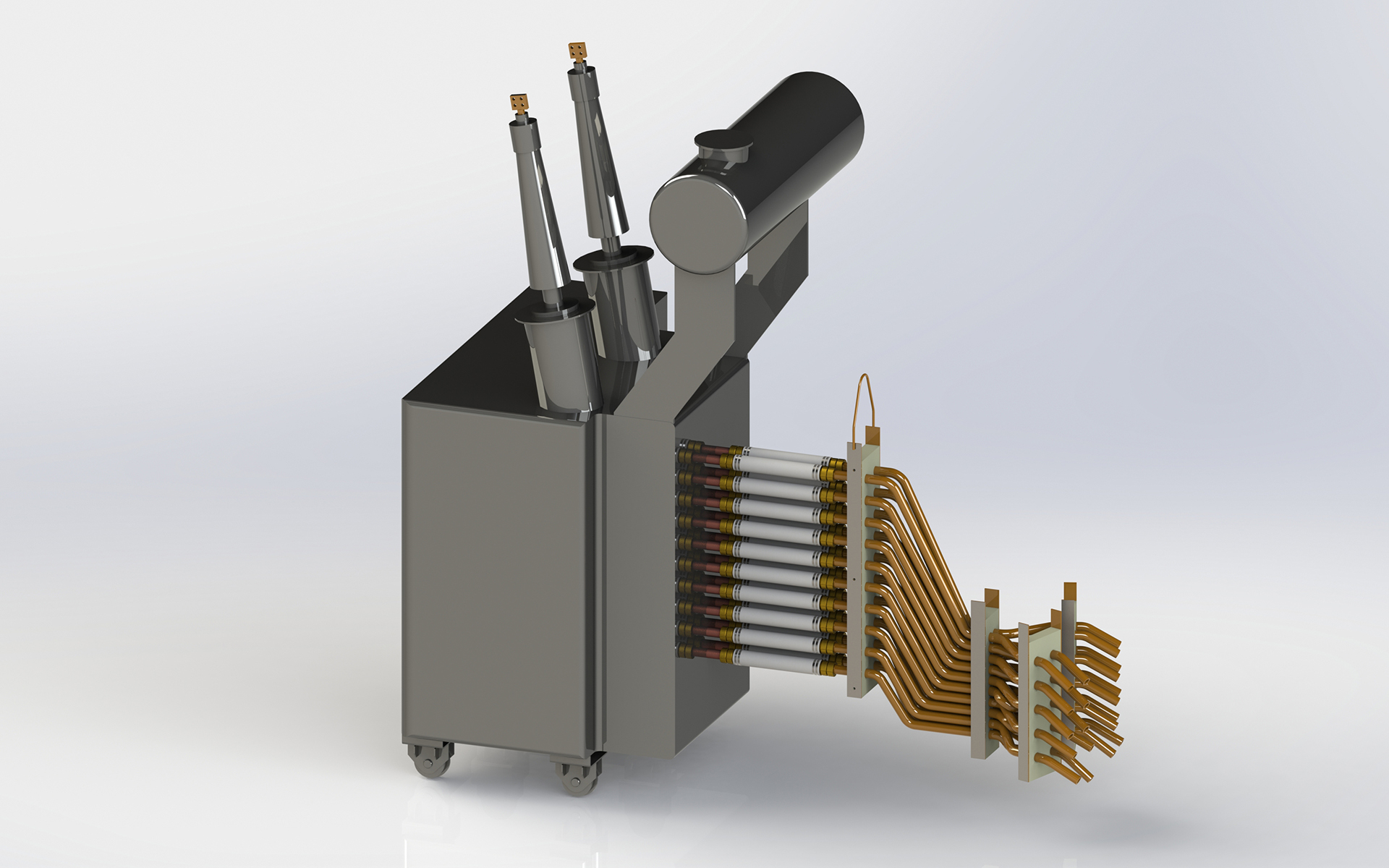

Moveable Arc Burner

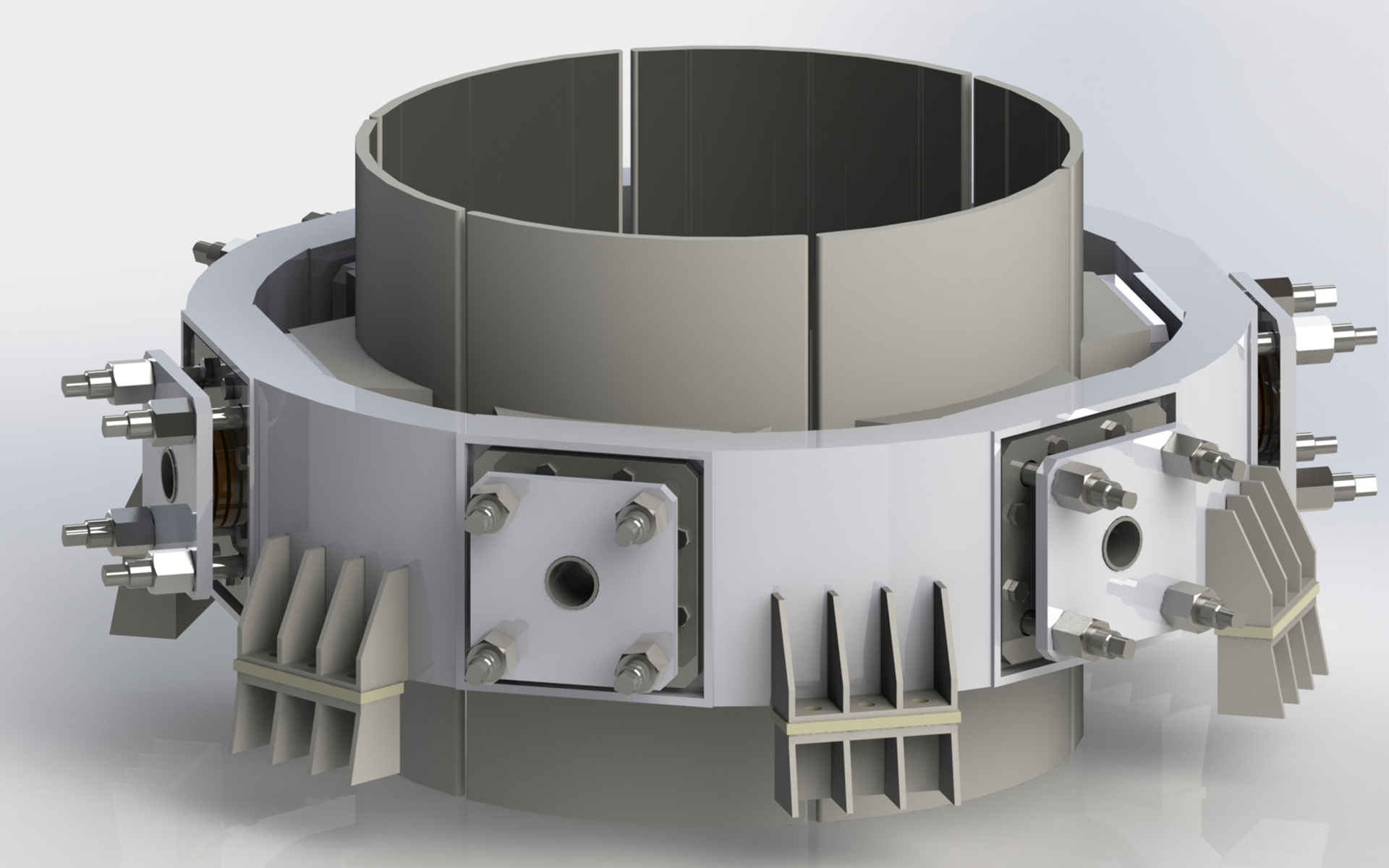

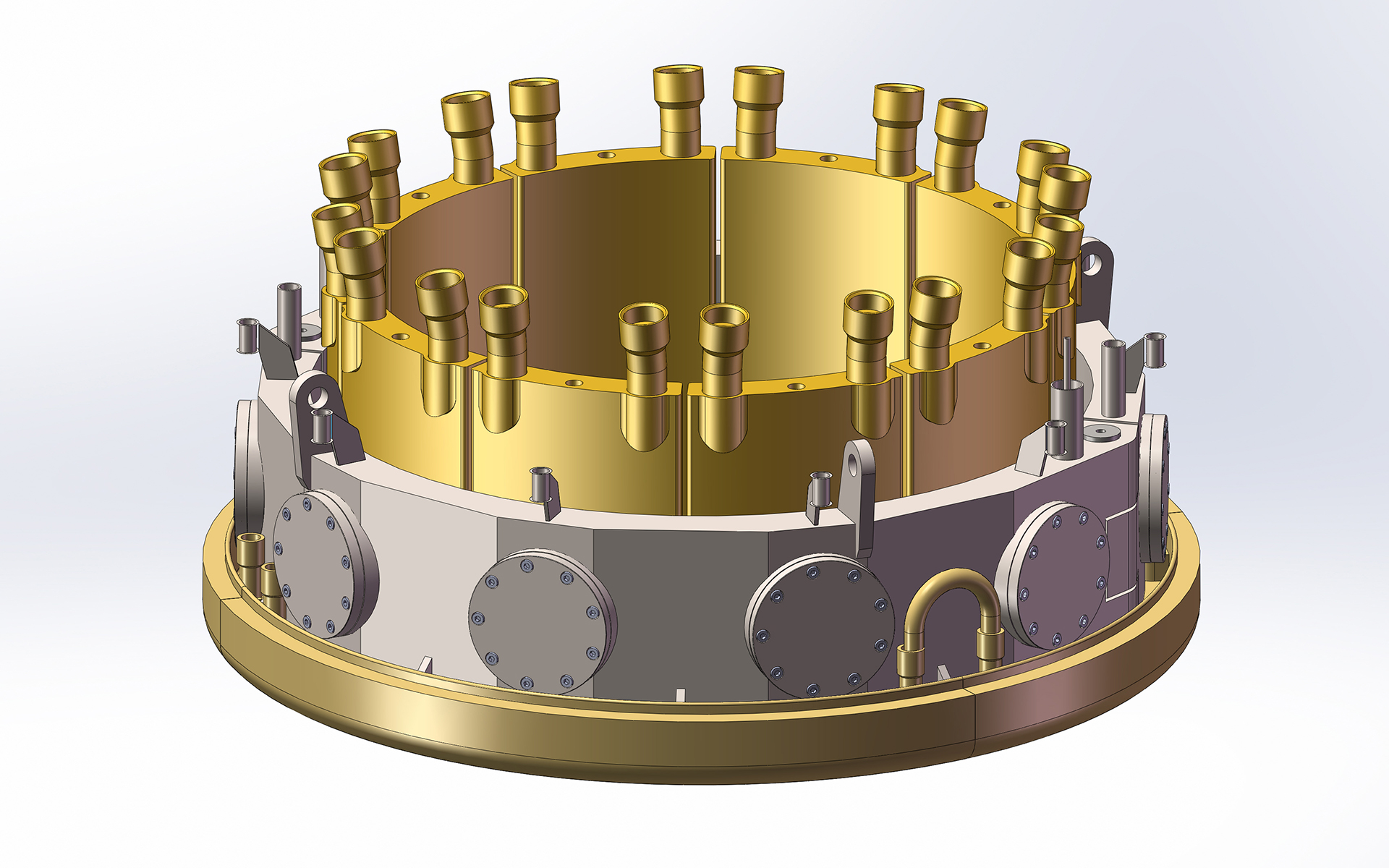

Pressure Ring

Short Net System

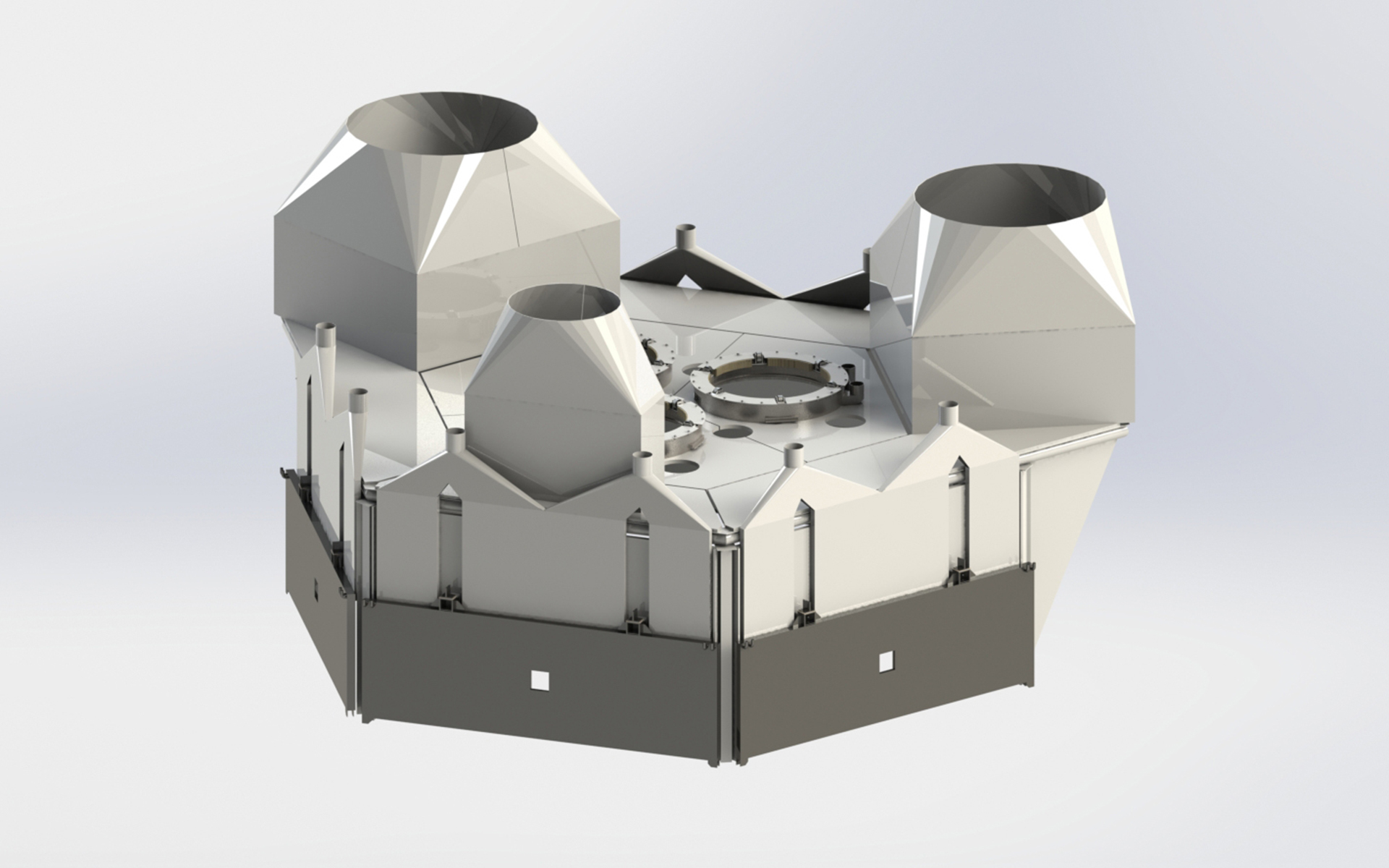

Smoke Hood