Ferro silicon is made of coke, steel chips, quartz (or silica) by ferro silicon furnace smelting. In traditional ferrosilicon smelting, silicon is reduced from silica containing SiO2. Metallurgical coke is mostly used as reductant in ferrosilicon smelting, and steel scraps are mainly for blending purpose.

The raw materials and electric energy consumption for producing one ton ferrosilicon are as follows:

- Silica quartz: 1780-1850kg

- Coke: 890-930kg

- Steel scraps: 220-230kg

- Electrode paste: 45-55kg

- Power consumption: 8400-9000kwh / T

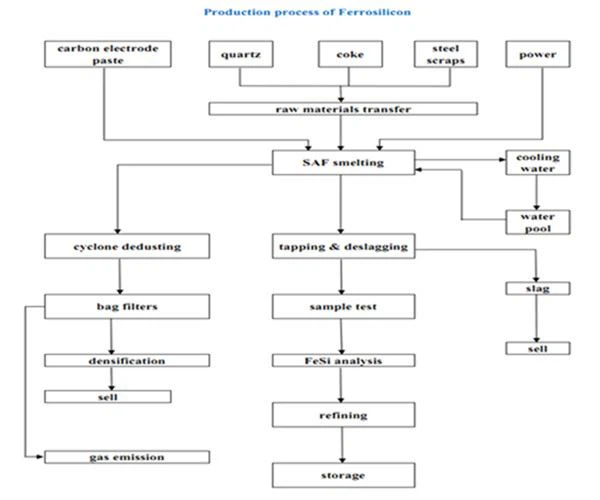

General smelting production process of ferro silicon furnace show as following graph:

Classifications of ferro silicon alloys can be refers to ISO standard as following table:

| Grade | chemical compositions % | |||||||||

| Si | Al | P | S | C | Mn | Cr | Ti | |||

| > | ≤ | > | ≤ | ≤ | ||||||

| FeSi10 | 8.0 | 13.0 | 0.2 | 0.15 | 0.06 | 2.0 | 3.0 | 0.8 | 0.3 | |

| FeSi15 | 14.0 | 13.0 | 1.0 | 0.15 | 0.06 | 1.5 | 1.5 | 0.8 | 0.3 | |

| FeSi25 | 20.0 | 20.0 | 1.5 | 0.15 | 0.06 | 1.0 | 1.0 | 0.8 | 0.3 | |

| FeSi45 | 41.0 | 30.0 | 2.0 | 0.05 | 0.05 | 0.2 | 1.0 | 0.5 | 0.3 | |

| FeSi50 | 47.0 | 47.0 | 1.5 | 0.05 | 0.05 | 0.2 | 0.8 | 0.5 | 0.3 | |

| FeSi65 | 63.0 | 51.0 | 2.0 | 0.05 | 0.04 | 0.2 | 0.4 | 0.4 | 0.3 | |

| FeSi75Al | 72.0 | 68.0 | 1.0 | 0.05 | 0.04 | 0.2 | 0.5 | 0.3 | 0.3 | |

| FeSi75Al1.5 | 72.0 | 80.0 | 1.0 | 1.5 | 0.05 | 0.04 | 0.2 | 0.5 | 0.3 | 0.3 |

| FeSi75Al2 | 72.0 | 80.0 | 1.5 | 2.0 | 0.05 | 0.04 | 0.2 | 0.5 | 0.3 | 0.3 |

| FeSi75Al3 | 72.0 | 80.0 | 2.0 | 3.0 | 0.05 | 0.04 | 0.2 | 0.5 | 0.5 | 0.3 |

| FeSi90Al1 | 87.0 | 95.0 | 1.5 | 0.04 | 0.04 | 0.2 | 0.5 | 0.2 | 0.3 | |

| FeSi90Al2 | 87.0 | 95.0 | 1.5 | 3.0 | 0.04 | 0.04 | 0.2 | 0.5 | 0.2 | 0.3 |

For any more details about ferro silicon furnace, please reach guoke1207@hotmail.com

Post time: Sep-07-2020