Medium Frequency Furnace

Medium Frequency Furnace

Product Description

Medium frequency furnace is a kind of power supply device that transforms power frequency 50Hz alternating current into medium frequency (over 300Hz to 1000Hz). It transforms three-phase power frequency alternating current into direct current after rectification, and then converts direct current into adjustable medium frequency current, which supplies medium frequency alternating current flowing through capacitor and induction coil, generates high-density magnetic lines in induction coil, and cuts metal materials contained in induction coil Material, in metal materials produce a large eddy current.

Working frequency of medium frequency induction furnace (hereinafter referred to as medium frequency furnace) is between 50-2000 Hz, which is widely used for smelting of non-ferrous metals and ferrous metals. Compared with other casting equipment, medium frequency induction furnace has advantages of high thermal efficiency, short melting time, less alloy element burning loss, wide melting material, less environmental pollution, and accurate control of temperature and composition of liquid metal.

Major equipment features of medium frequency furnace are show as following:

1- Costs saving

- High heating speed, high production efficiency, less oxidation and decarburization, material and cost saving, and extended mold life

2- Environmental protection

- Superior working environment, improved working environment and company image, pollution-free and low energy consumption

- Uniform heating, small temperature difference between core and surface, high temperature control accuracy

3- Characteristics of medium frequency smelting

- smelting speed is fast, power saving effect is good, burning loss is less and energy consumption is low.

- self stirring function, melting temperature and metal composition are uniform.

- the working environment of electric heating is good.

- good startup performance, 100% startup for both empty and full furnaces

Technical parameters (example)

- 5T/2500KW Medium frequency furnace (steel shell) technical parameters

| Name | Unit | Data | Remarks |

| Furnace parameters | |||

| Rated capacity | t | 5.0 | Molten metal |

| Max capacity | t | 5.5 | Molten metal |

| Work temperature | ℃ | 1600 | |

| Max work temperature | ℃ | 1750 | |

| Lining thickness | mm | 150 | |

| Coil ID φ | mm | 1410 | |

| Coil height | mm | 1620 | |

| Electrics parameters | |||

| Transformer capacity | KVA | 3150 | |

| Transformer primary voltage | KV | 10 | |

| Transformer secondary voltage | V | 900 | 12 Pulse double output |

| Rated power of intermediate frequency power supply | KW | 3000 | 12 Pulse double input |

| Rated input current | A | 2280 | |

| DC voltage | V | 1200 | |

| DC current | A | 1500 | |

| Transformation efficiency | % | 96 | |

| Start success rate | % | 100 | |

| Maximum output voltage of if power supply | V | 1700 | |

| Rated working frequency | Hz | 350 | |

| Power conversion efficiency | % | 96 | |

| Working noise | db | ≤75 | |

| Comprehensive parameters | |||

| Melting rate (up to 1600℃) | T/h | 4.96 | Depends on furnace charging |

| Power consumption (up to 1600℃) | KW.h/T | Less than 530 | |

| Cooling g water system | |||

| Water flow | T/h | 80 | |

| Water pressure | Mpa | 0.25-0.35 | |

| Flow-in water temperature | ℃ | 5-35 | |

| Flow-out water temperature | ℃ | <55 |

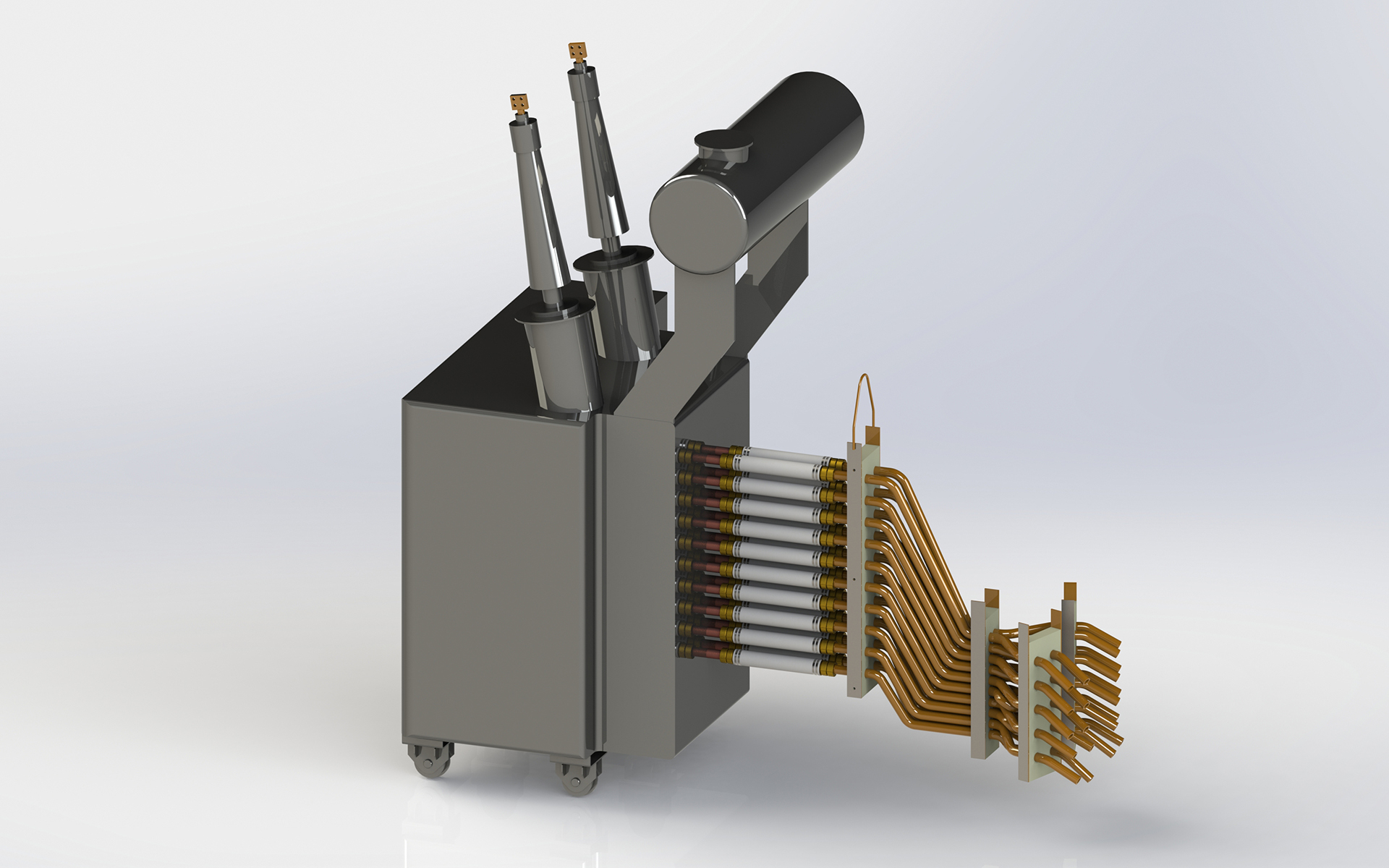

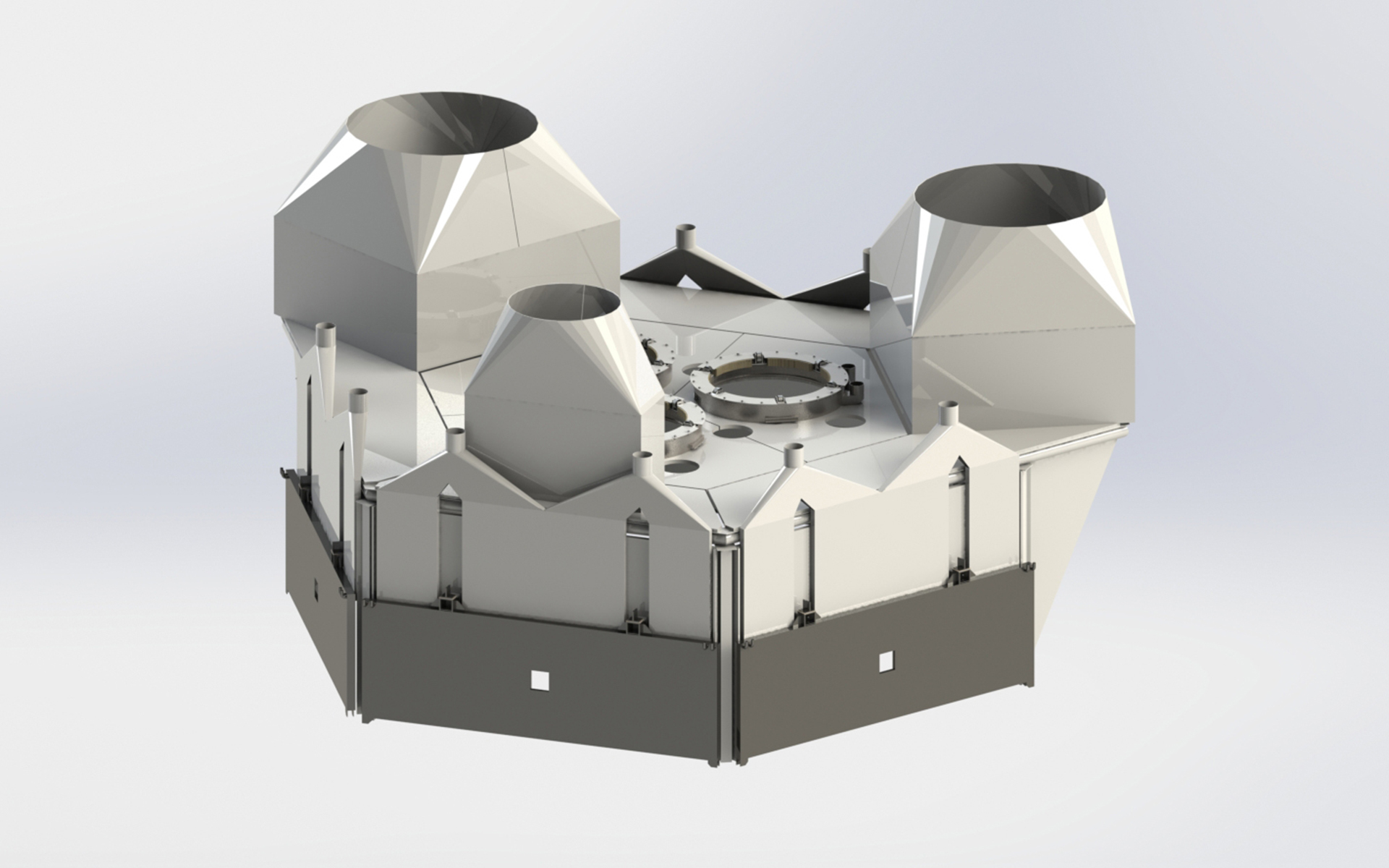

Parts Drawing

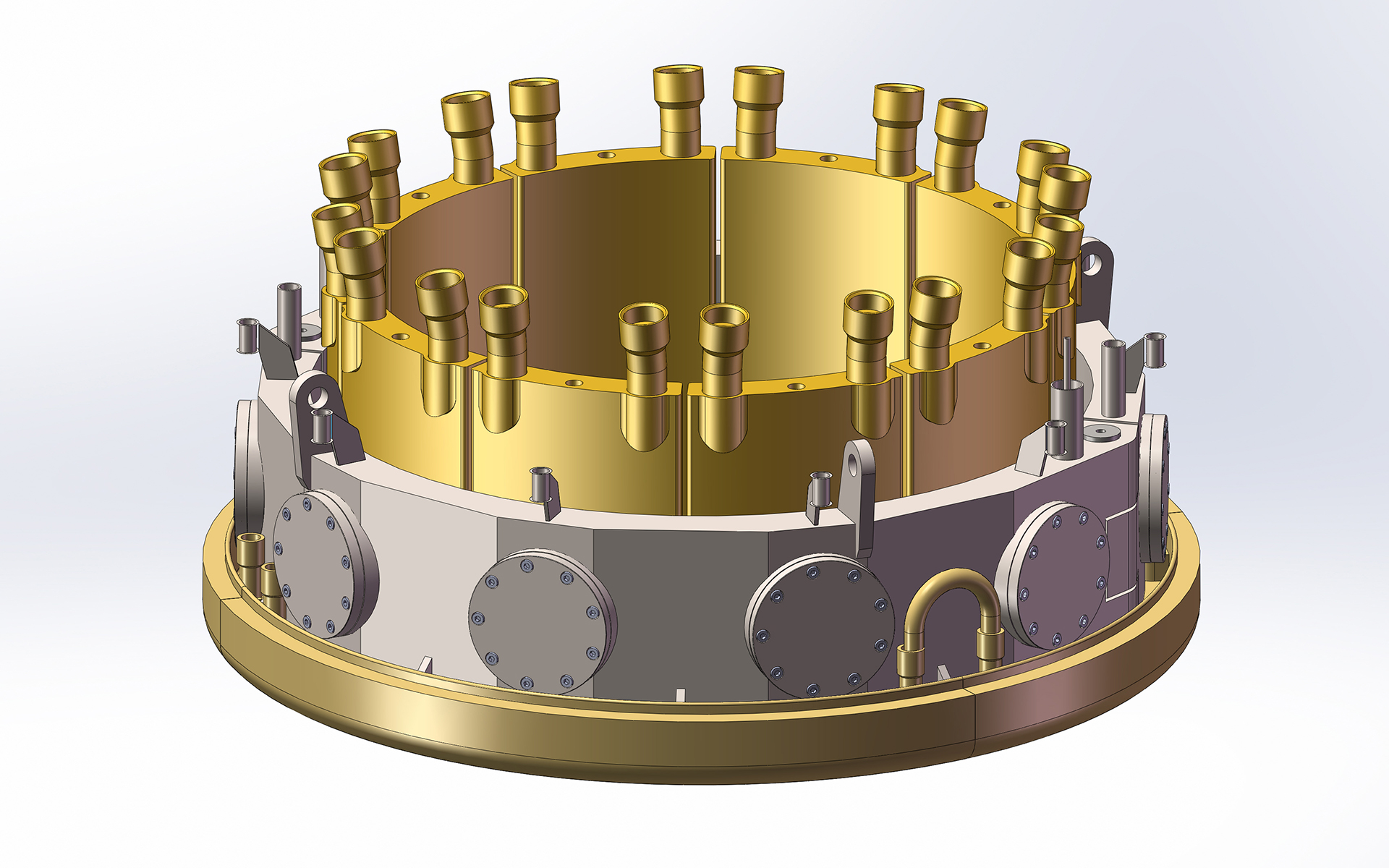

Copper Pipe Row

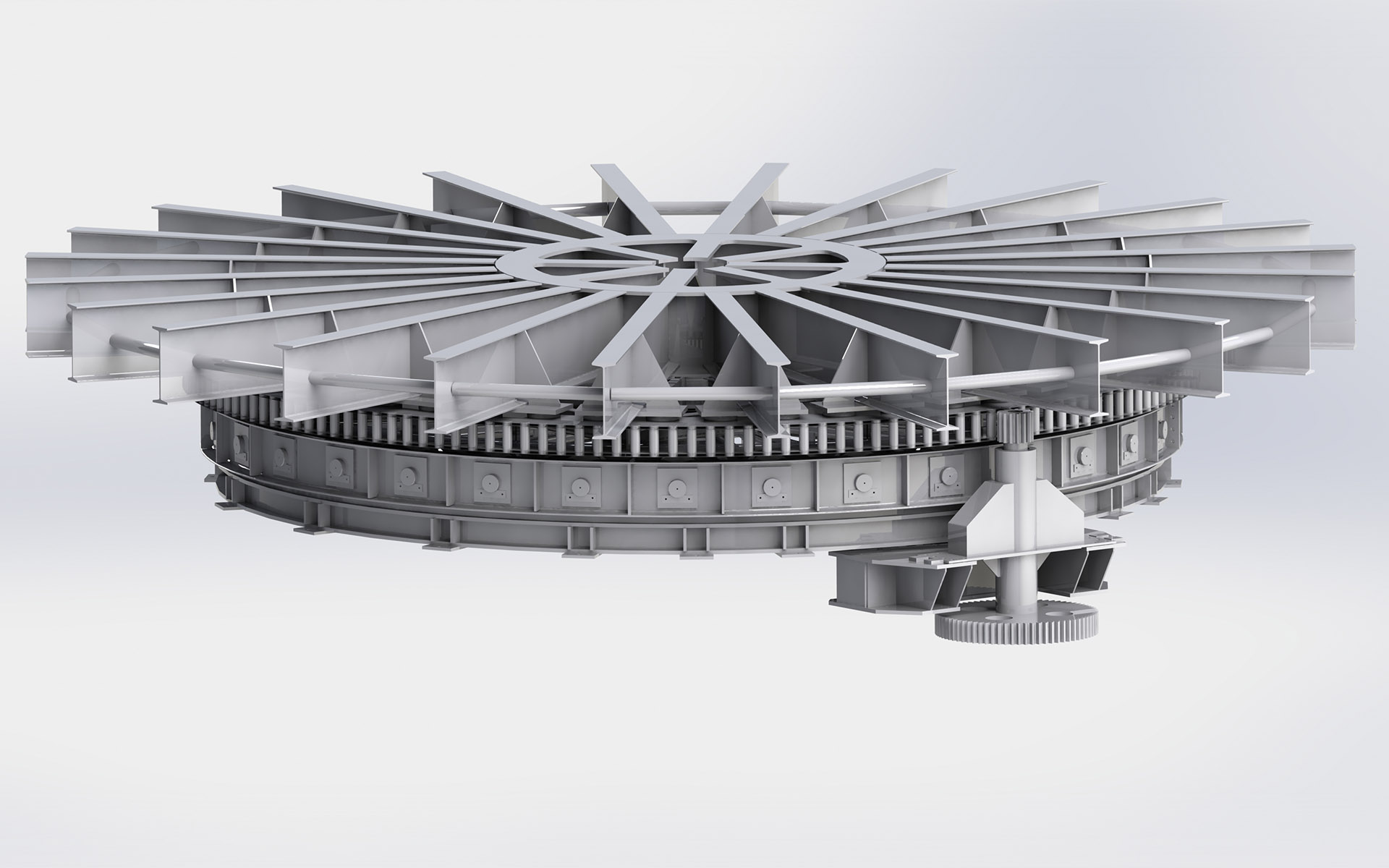

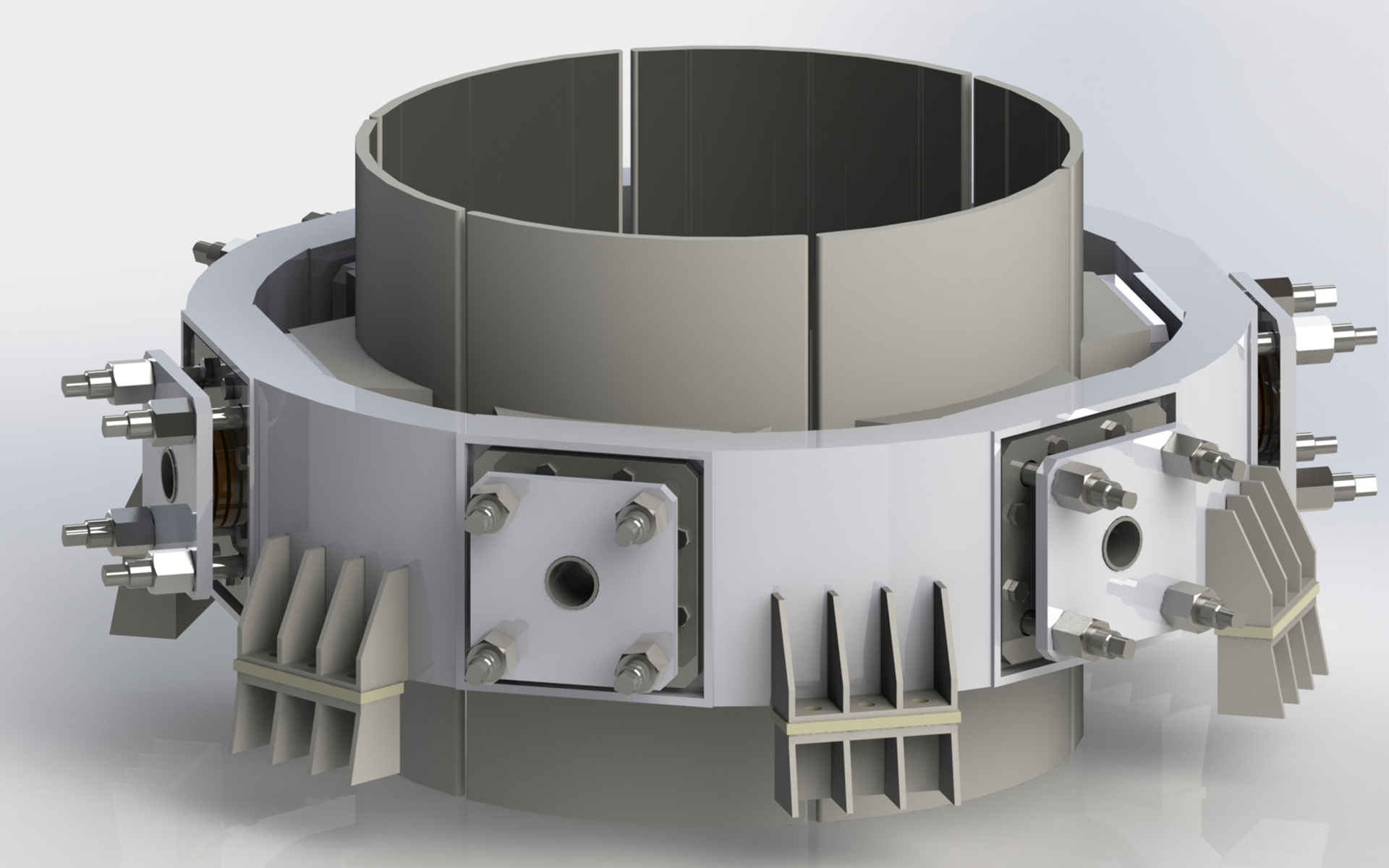

Furnace Rotating system

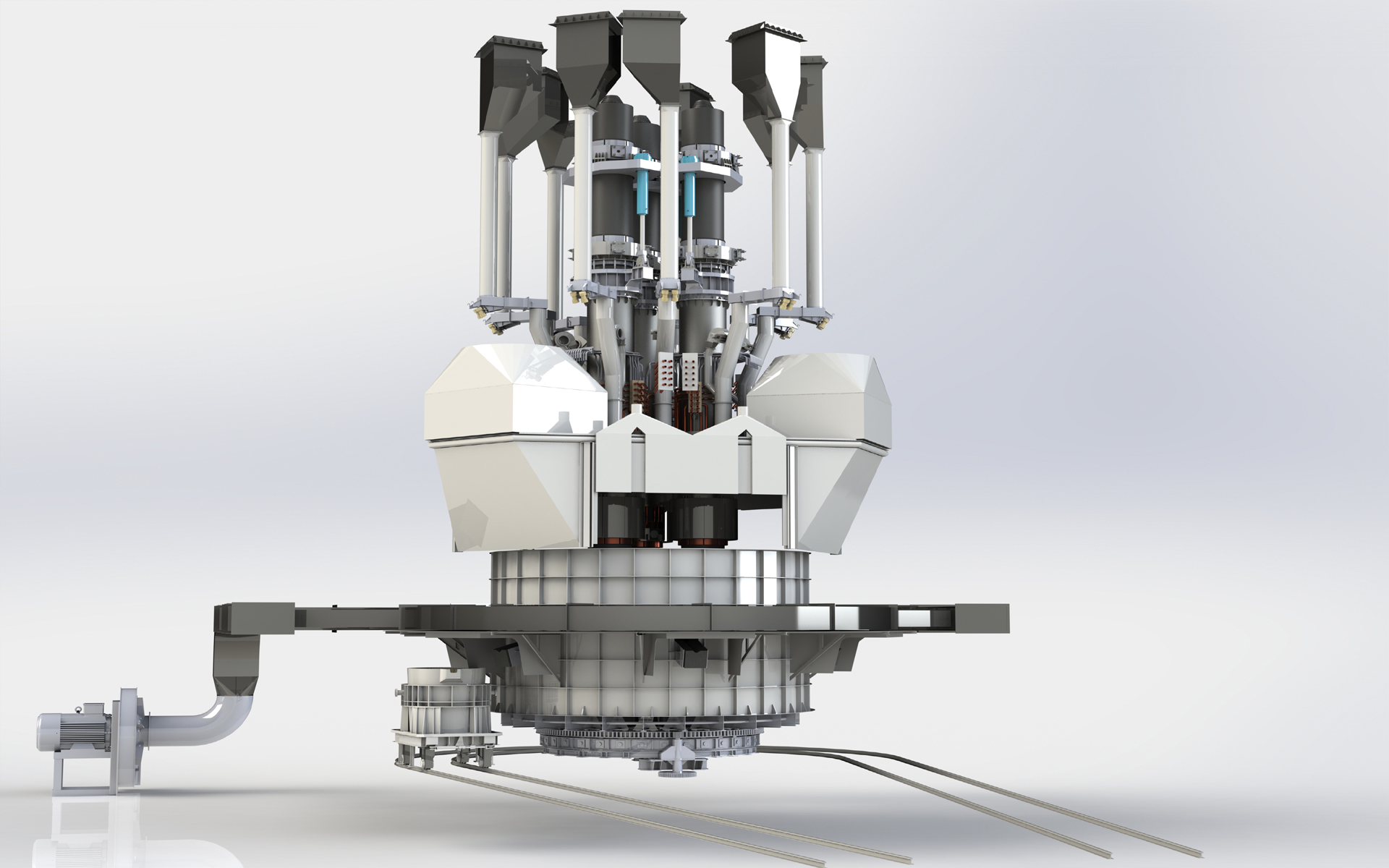

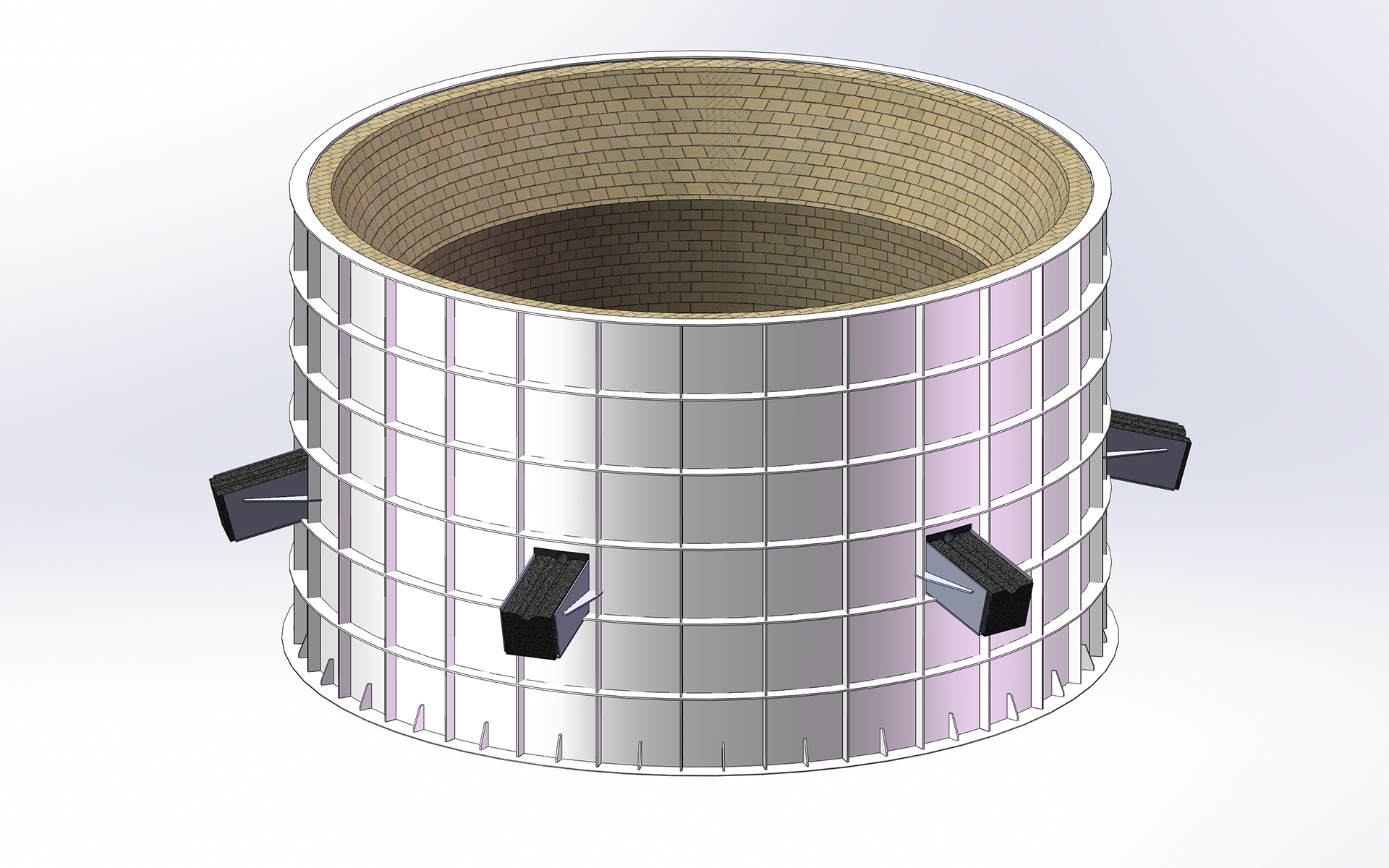

Furnace Assembly

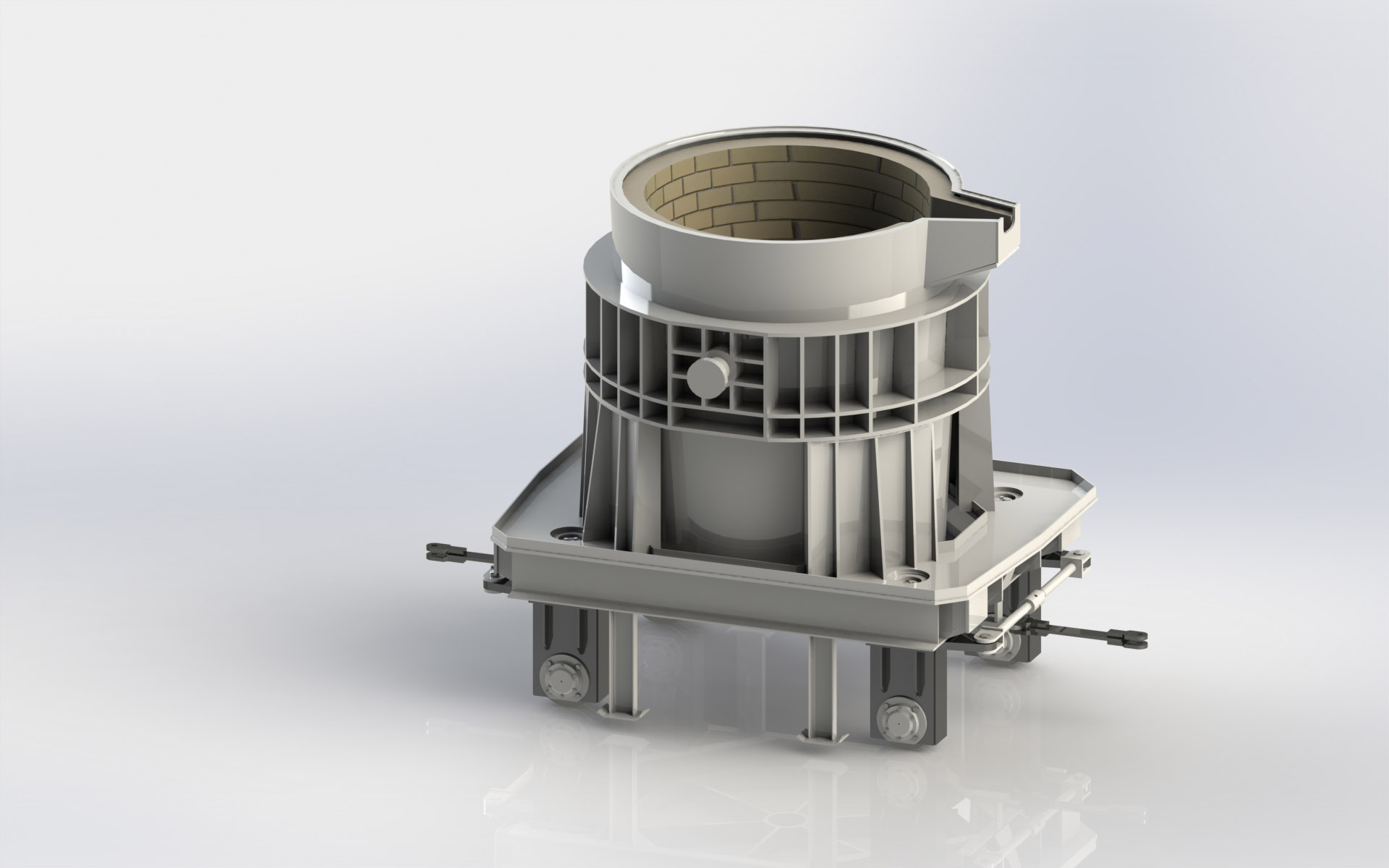

Furnace Shell

Upholding Brake

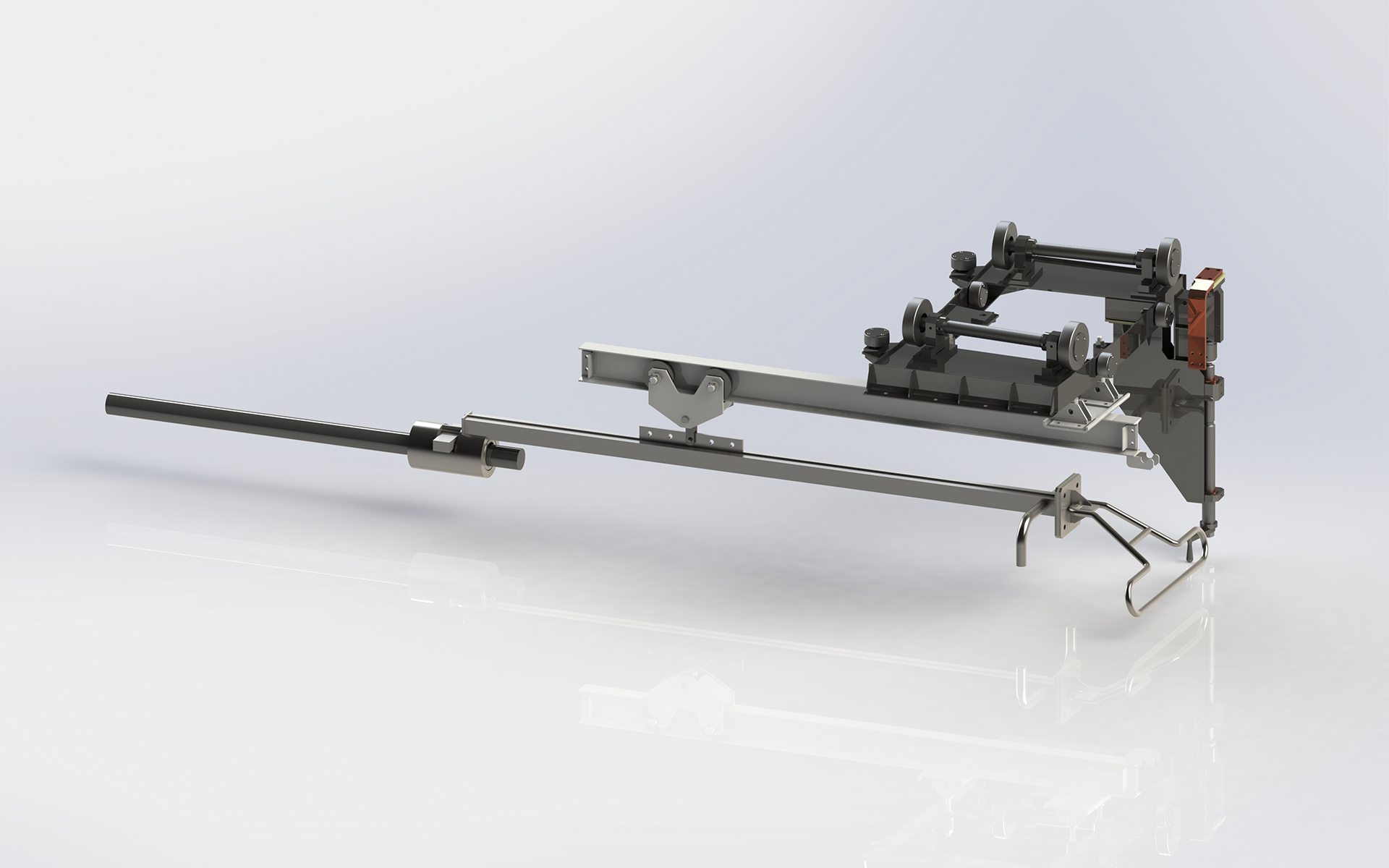

Moveable Arc Burner

Pressure Ring

Short Net System

Smoke Hood