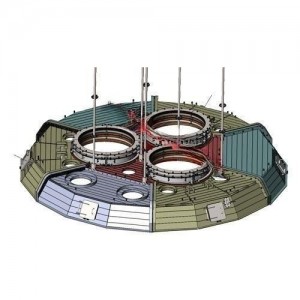

Manganese Rich Slag Furnace

Manganese Rich Slag Furnace

Product Description

Manganese rich slag furnace is one of major equipments for manganese extractions from lower Mn content manganese ores.

Manganese rich slag, also called manganese residual, is an intermediate product in smelting process of manganese ore, and then refined into manganese metal. Its production is to make iron and phosphorus fully reduced in a lower furnace temperature and acid slag by adding insufficient carbon as reductant to the high iron and phosphorus poor manganese ore which can not be directly used for smelting, and to make manganese stay in the slag to maximum extent, so as to obtain high manganese, low iron and low phosphorus rich manganese slag and high iron, high phosphorus and low manganese by-product iron. Manganese rich slag can be further refined to obtain metal manganese, which can also be used as a product for other purposes.

Classifications of manganese residual

| Grade | Chemical composition% | ||||

| Mn | Fe | P | |||

| Code | ≥ | Class 1 | Class 2 | Class 1 | Class 2 |

| ≤ | ≤ | ||||

| FMnZn 1 | 46 | 1.5 | 2.5 | 0.015 | 0.035 |

| FMnZn 2 | 44 | 1.5 | 2.5 | 0.015 | 0.035 |

| FMnZn 3 | 42 | 1.5 | 2.5 | 0.015 | 0.035 |

| FMnZn 4 | 40 | 1.5 | 2.5 | 0.015 | 0.035 |

| FMnZn 5 | 38 | 2 | 3 | 0.02 | 0.04 |

| FMnZn 6 | 36 | 2 | 3 | 0.02 | 0.04 |

| FMnZn 7 | 34 | 2 | 3 | 0.02 | 0.04

|

Product Detail

After manganese rich slag furnace smelting, the product can be used :

1- As raw materials of silicon manganese;

2- As raw materials of Mn metal;

3- As raw materials of submerged arc furnace ferromanganese and medium/low carbon ferromanganese;

4- As raw materials of blast furnace ferromanganese.