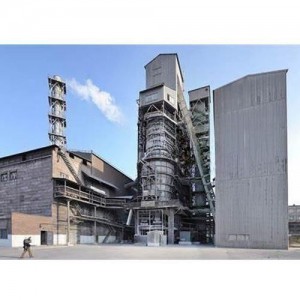

Lime Furnace

Lime Furnace

Product Description

Lime furnace is a kind of kilns with vertical furnace body, continuous feeding, used to calcine limestone and decompose limestone into quicklime CaO and CO2 at high temperature.

Technological process:

Limestone and fuel are put into lime kiln (if gas fuel is sent through pipeline and burner) and preheated, decomposed to 850 ℃, calcined at 1200 ℃, and then discharged out of kiln after cooling. That is to complete production of quicklime products. Different kiln shapes have different preheating, calcination, cooling and ash unloading methods. However, there are several same principles: high quality of raw materials and good quality of lime; high calorific value of fuel and less consumption of quantity; and

Particle size of limestone is directly proportional to calcination time, and activity of quicklime is inversely proportional to calcination time and temperature.

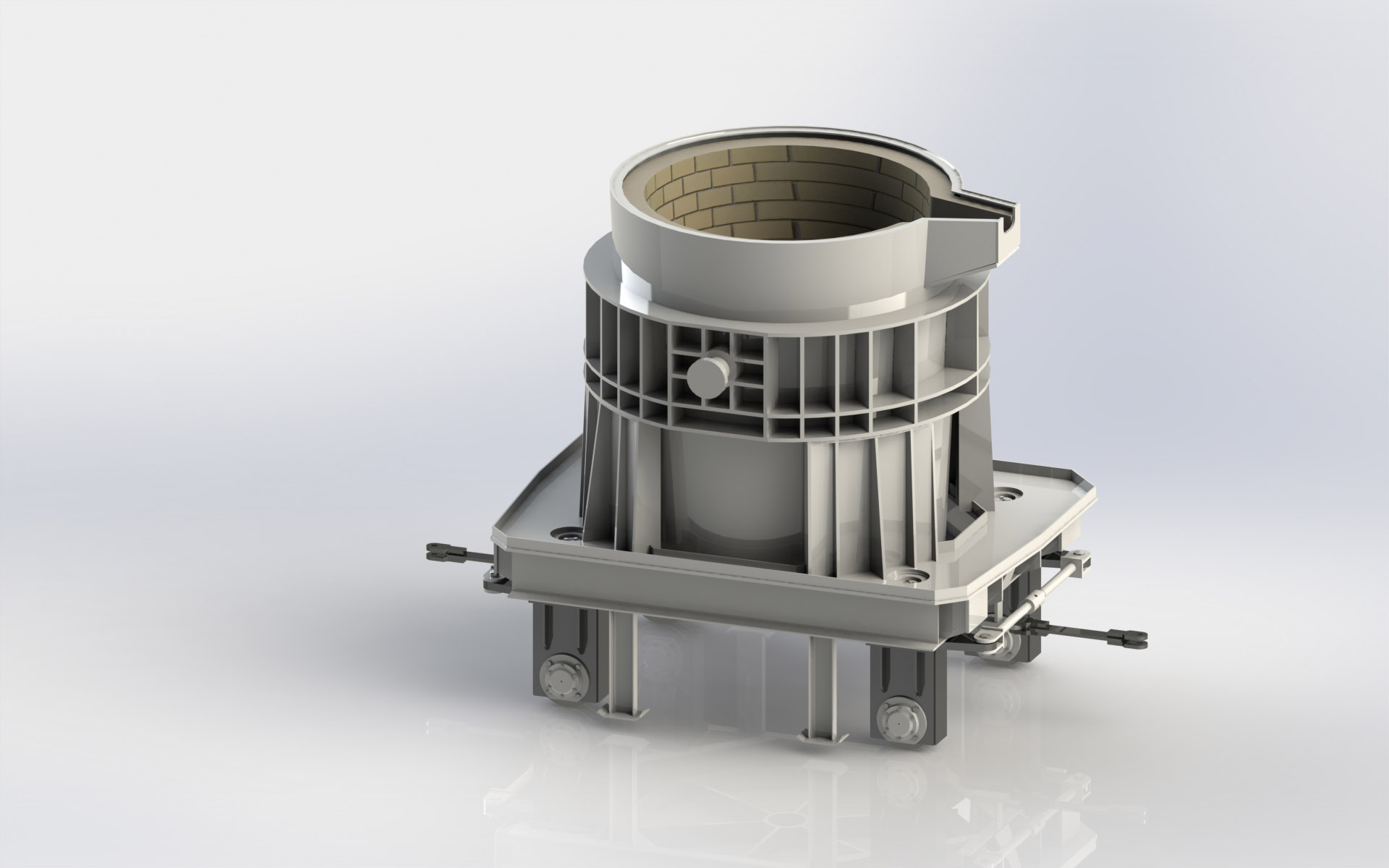

Basic structure and principle:

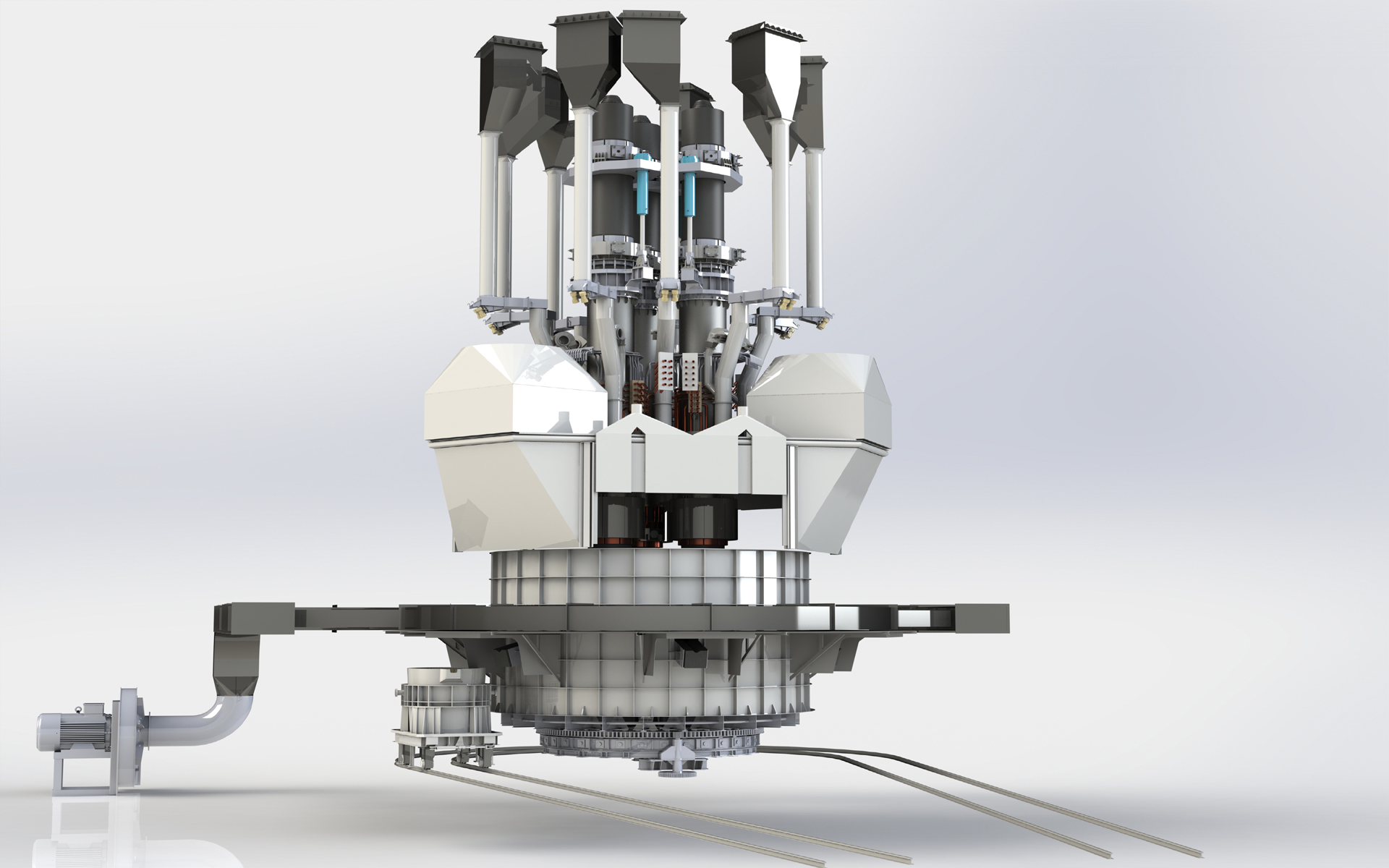

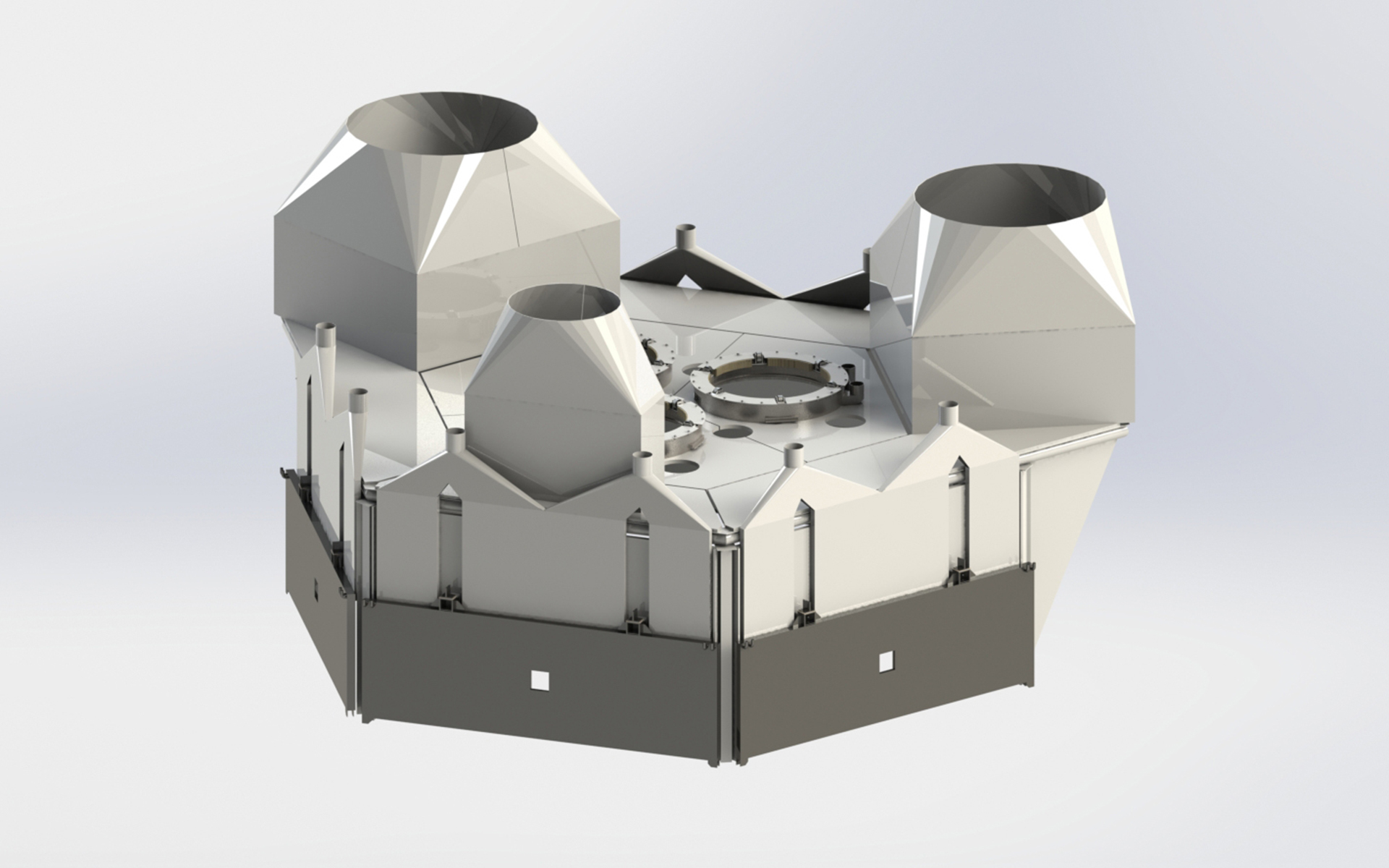

Lime furnace is mainly composed of furnace body, feeding device, distribution device, combustion device, ash unloading device, electrical appliances, instrument control device, dust removal device, etc.

Different forms of lime kiln, its structure and calcination form are different, process flow is basically the same, but equipment value is very different. Of course, effect of use is certainly different. Calcined quicklime has a long history in China, and quality of lime is required to be higher and higher.

Main technical and economic indexes of lime furnace:

1: Effective volume of furnace 100-350 (M3)

2: Yield 85-300 (T/D)

3: Heat consumption 960 × 4.1868 (kJ / kg · T; lime) standard coal consumption 130 (kg/kg·lime)

4: Utilization coefficient > 0.85 (T/D·m3)

5: Activity ≥ 300 (ML)

6: Quicklime content ≥ 90 Cao (%)

7: The over burning rate of quicklime is less than 5-7%

8: Limestone consumption 1.8 (T/T ·ash)

9: Concentration of CO2 in flue gas 42 (%) 250m3 furnace produces CO2 gas per hour 10 (T)

10: Smoke emission index < 50 (mg / m3)

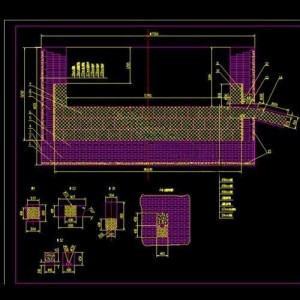

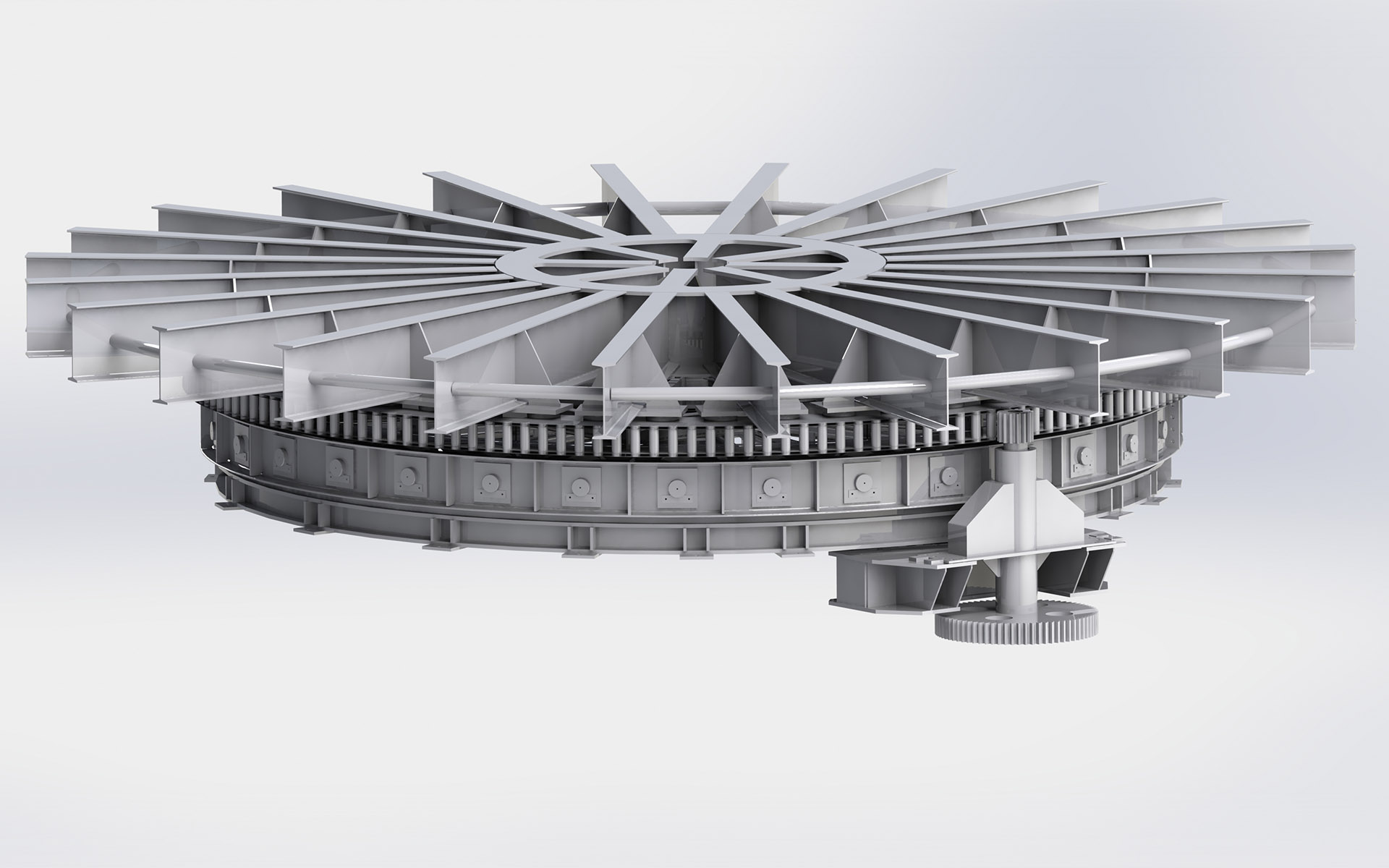

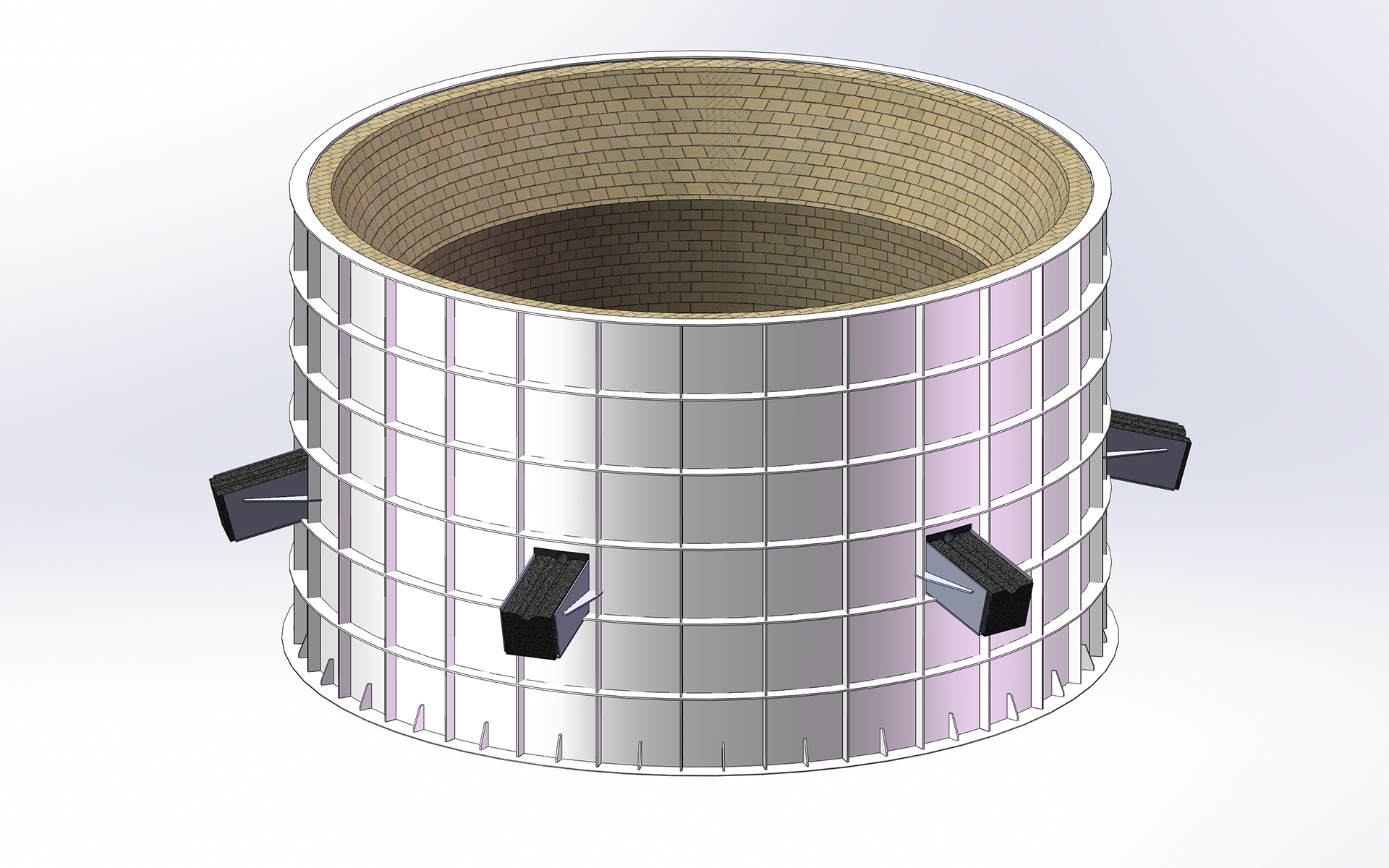

Parts Drawing

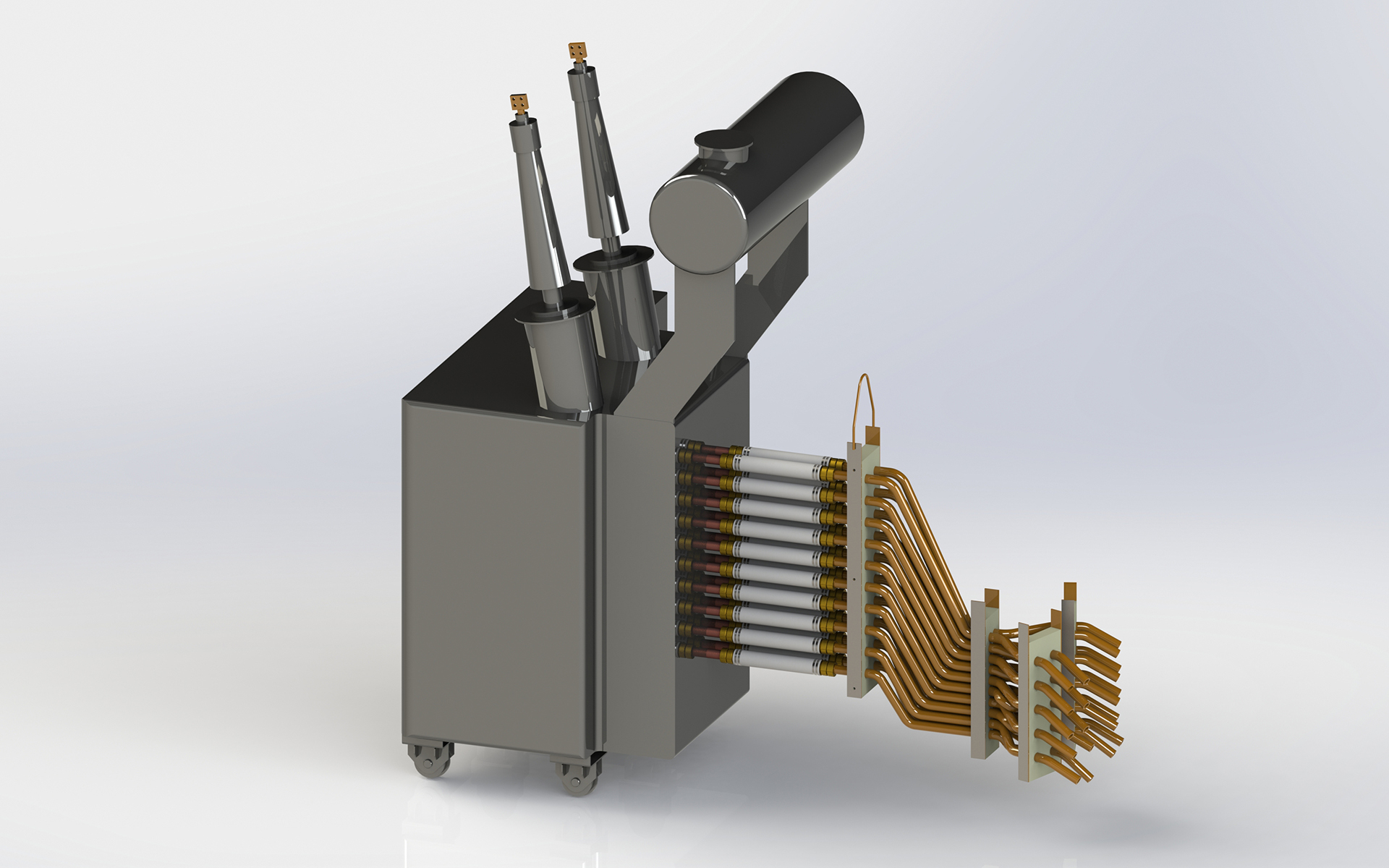

Copper Pipe Row

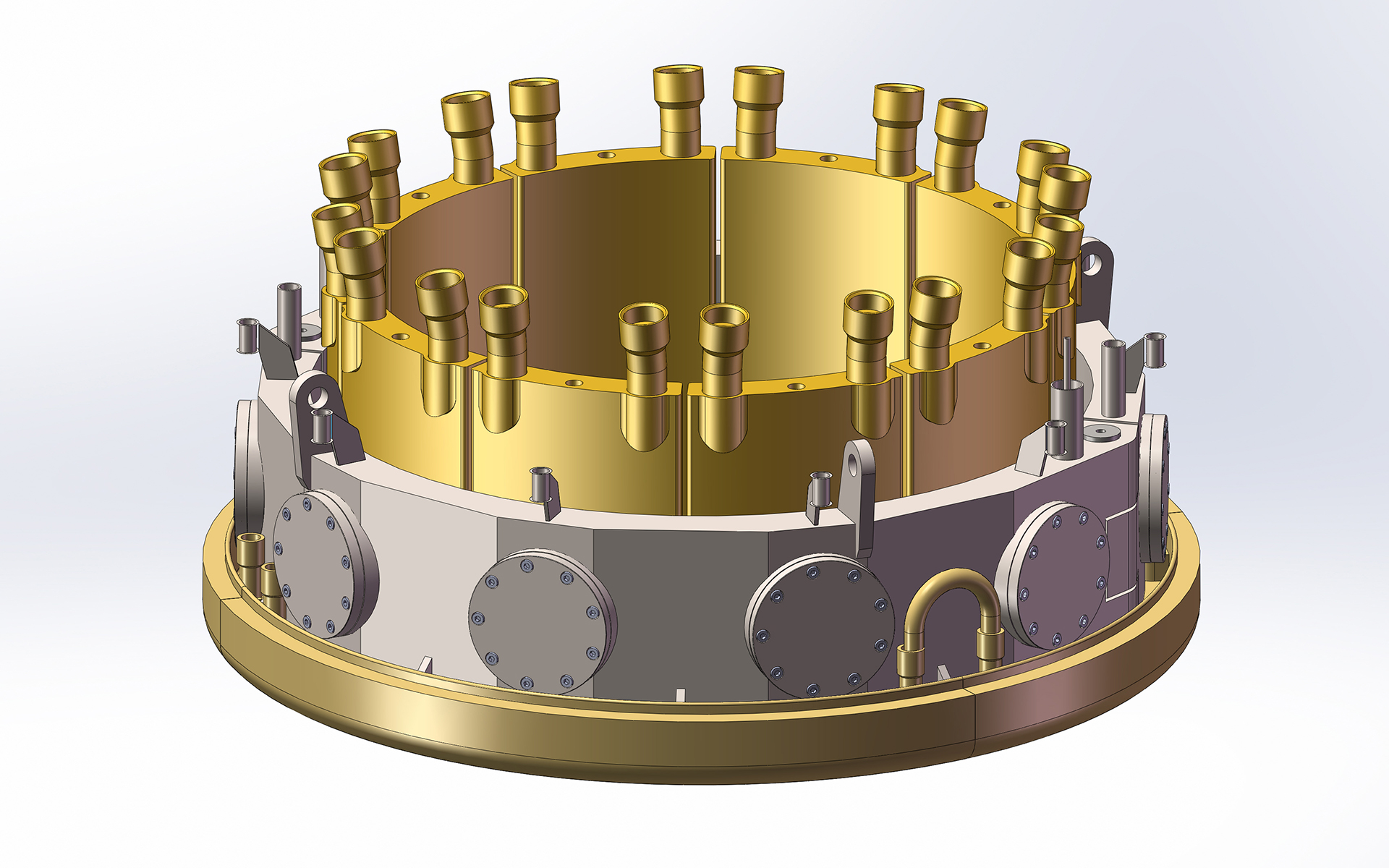

Furnace Rotating system

Furnace Assembly

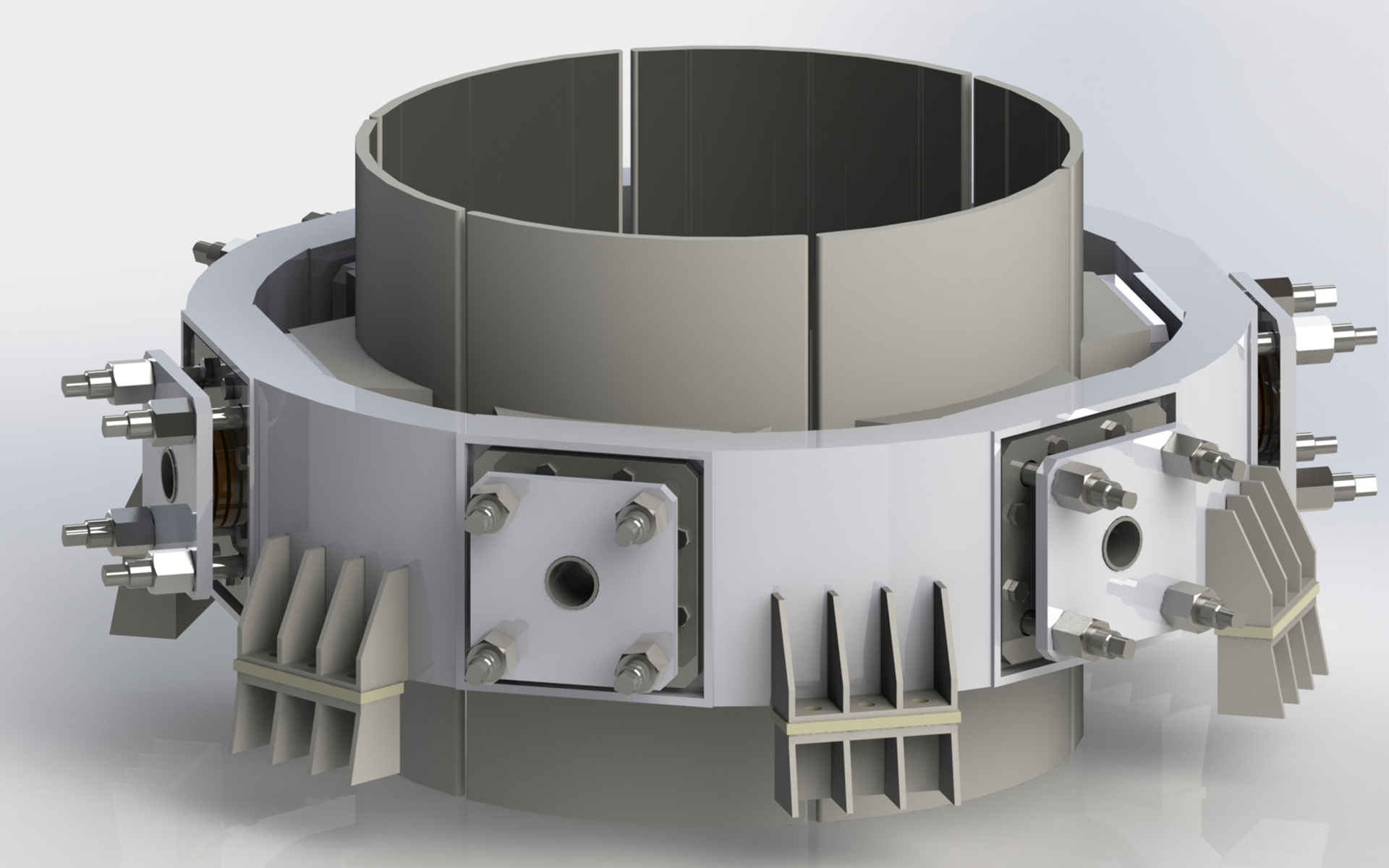

Furnace Shell

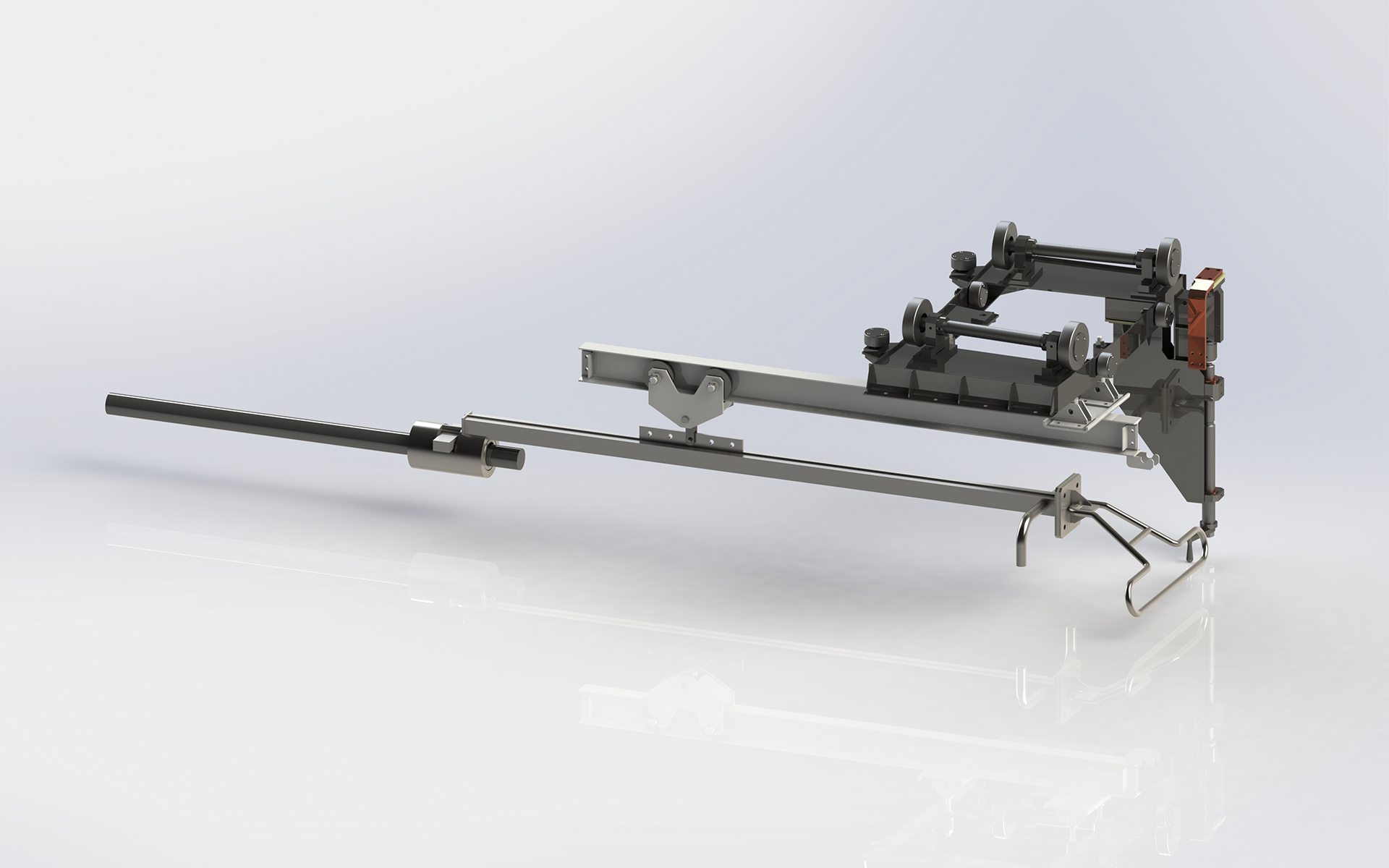

Upholding Brake

Moveable Arc Burner

Pressure Ring

Short Net System

Smoke Hood