Ferro Silicon Furnace

Ferro Silicon Furnace

Product Description

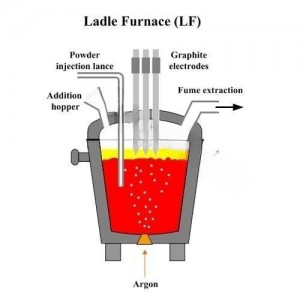

Ferro silicon furnace is the applications of submerged arc furnace for ferrosilicon alloys production.

Ferrosilicon is usually smelted in closed submerged arc furnaces with different power to producer different purities of Ferrosilicon alloy, in which FeSi 75 is the most popular one.

Raw materials of ferrosilicon production mainly includes silica quartz, coke (semi coke) , scrap iron, millscale, or other source of iron.

Raw materials consumptions of ferro silicon production (33000KVA,75% Si)are show as :

| No | Items | Consumptions |

| 1 | Silica quartz | 1780~1850kg/t |

| 2 | Coke | 890~930 kg/t |

| 3 | Millscale | 220~230 kg/t |

| 4 | Carbon electrode paste | 45~55 kg/t |

| 5 | Power | 8100~8600Kw.h/t |

Types of ferro silicon furnace can be classified as :

-1- semi closed and closed.

-2- with or without rotating structure.

We are experienced manufacturer of ferrosilicon furnaces and supplied proper equipments and technologies for many ferrosilicon producers in past decade years. The minimum capacity of ferrosilicon furnace for ferrosilicon producers is 33000KVA at present.