Electrotherm Induction Furnace

Electrotherm Induction Furnace

Product Description

Electrotherm induction furnace or induction furnace, is an industrial furnace that melts metals by electromagnetic induction.

It adopts three kinds of AC power supply: power frequency (50 Hz or 60 Hz), medium frequency (60-10000 Hz) and high frequency (higher than 10000 Hz).

It can also divided into induction furnace and induction heating equipment. The former is used for melting or heat preservation of materials, and the latter is used for heating materials, including uniform heating of materials as a whole, surface heating or local heating.

Electrotherm induction furnace product Description:

Induction furnace is composed with several components including frequency converter, furnace body and furnace control system. Three-phase SCR power supply is alternating current through the rectifier circuit frequency change to the DC, through the inverter circuit output to a single phase AC and supply to frequency coreless medium frequency induction furnace, and then use electromagnetic induction principle to put work piece to the alternating magnetic field to generate eddy which then match the requirement in melting, quenching and etc.

Technical Parameters:

| Name | Model | Rated Capacity(t) | Rated Power (kw) | Rated Frequency (Hz) | Rated Tem. (℃) | Melting Rate(t/h) |

| Furnace for Iron and Steel melting | GW-0.15-1/100 | 0.15 | 100 | 1000 | 1600 | 0.12 |

| GW-0.25-1/160 | 0.25 | 160 | 1000 | 1600 | 0.25 | |

| GW-0.5-1/250 | 0.5 | 250 | 1000 | 1600 | 0.4 | |

| GW-1-(0.5-1)/500 | 1 | 500 | 500-1000 | 1600 | 0.85 | |

| GW-1.5-(0.5-1)/750 | 1.5 | 750 | 500-1000 | 1600 | 1.25 | |

| GW-2.0-0.5/1000 | 2.0 | 1000 | 500 | 1600 | 1.8 | |

| GW-3.0-0.5/1500 | 3.0 | 1500 | 500 | 1600 | 2.5 | |

| GW-5.0-0.5/2000-2500 | 5.0 | 2500-3000 | 500 | 1600 | 4.2/5.0 | |

| GW-8.0-(0.4-0.5) /4000-5000 |

8.0 | 4000-5000 | 400-500 | 1600 | 6.8-8.5 | |

| GW-10-(0.2-0.5)/ 5000-6000 |

10 | 5000-6000 | 200-500 | 1600 | 8.5-10 | |

| GW-15-(0.2-0.3)/8000 | 15 | 8000 | 200-300 | 1600 | 13.5 | |

| Furnace for aluminum melting | GWL-0.3-1/160 | 0.3 | 160 | 1000 | 750 | 0.25 |

| GWL-0.5-1/300 | 0.5 | 300 | 1000 | 750 | 0.60 | |

| GWL-0.8-1/400 | 0.8 | 400 | 1000 | 750 | 0.75 | |

| GWL-1-0.5/500 | 1.0 | 500 | 500 | 750 | 0.95 | |

| GWL-1.5-0.5/800 | 1.5 | 800 | 500 | 750 | 1.40 | |

| Furnace for Copper melting | GWT-0.5-1/250 | 0.5 | 250 | 1000 | 1250 | 0.65 |

| GWT-1-1/500 | 1.0 | 500 | 500 | 1250 | 1.20 | |

| GWT-1.5-1/800 | 1.5 | 800 | 500 | 1250 | 1.8 | |

| GWT-3.0-0.5/1200 | 3.0 | 1200 | 500 | 1250 | 3.10 | |

| Holding furnace with capacity from 3T to 15T |

GWB-3.0-1/350 | 3.0 | 350 | 1000 | 1450 | 7(up to 100℃) |

| GWB-5.0-0.5/500 | 5.0 | 500 | 500 | 1450 | 10(up to 100℃) | |

| GWB-10-0.5/800 | 10 | 800 | 500 | 1450 | 18(up to 100℃) | |

| GWB-15-0.5/1000 | 15 | 1000 | 200 | 1450 | 22(up to 100℃) |

Parts Drawing

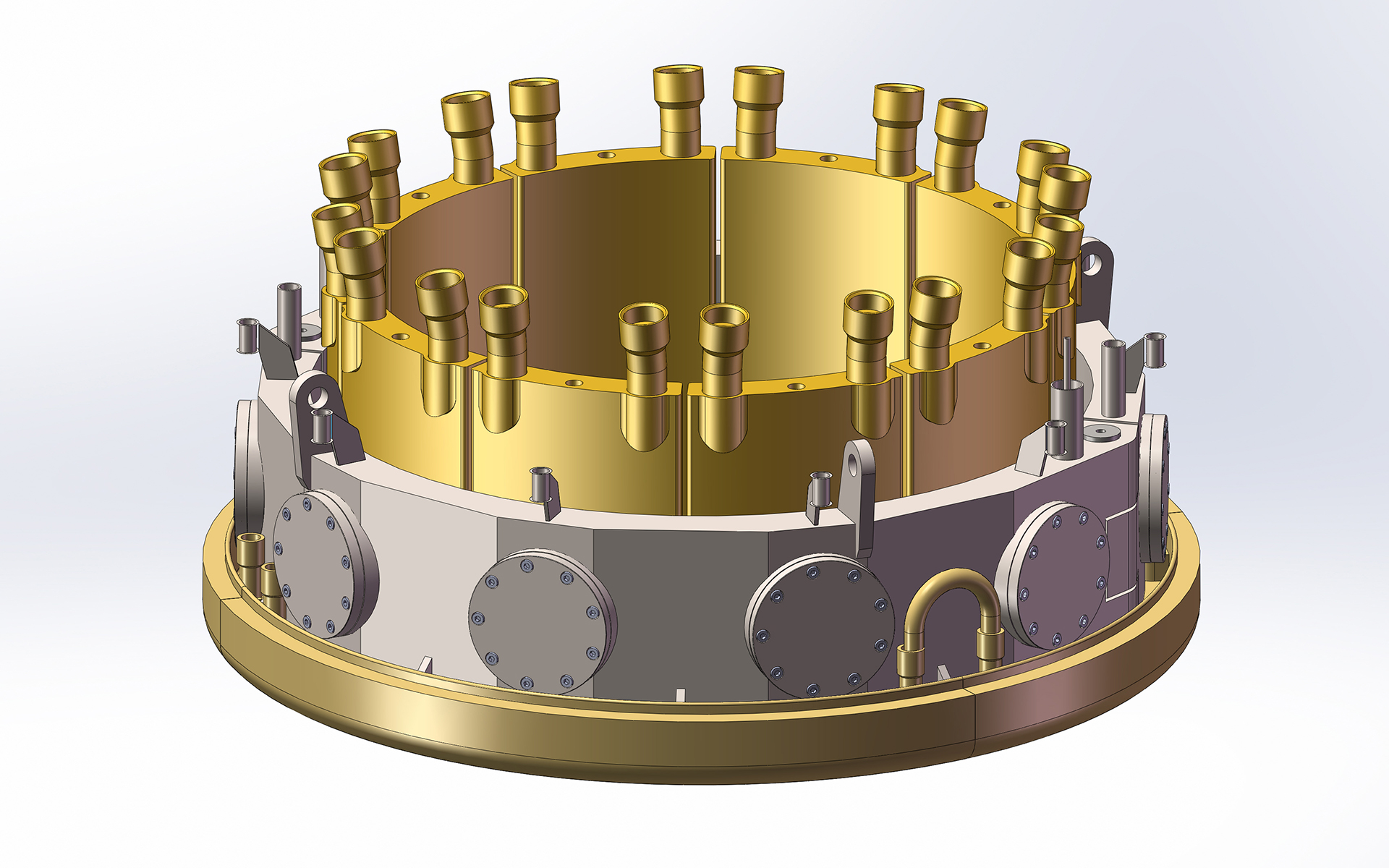

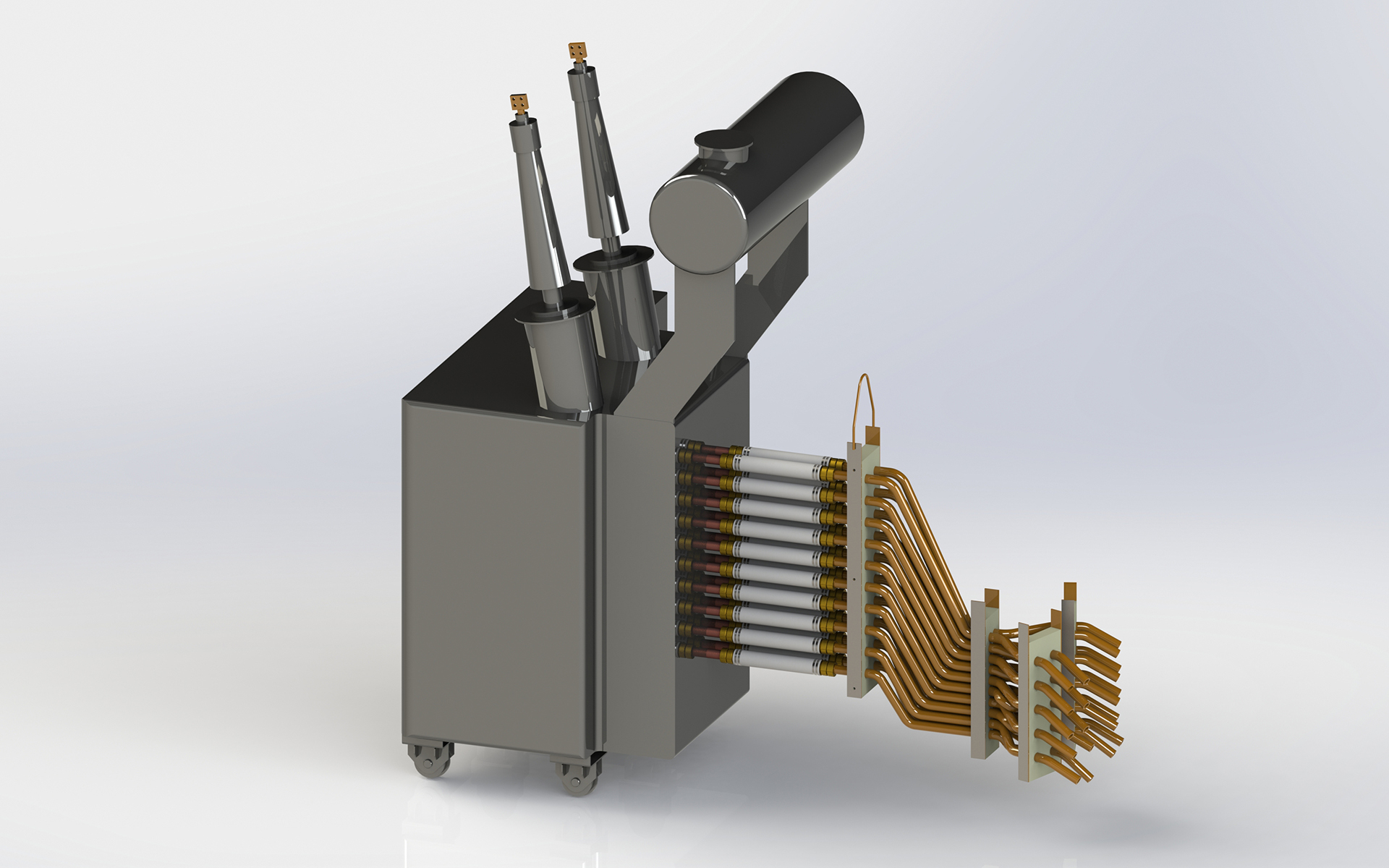

Copper Pipe Row

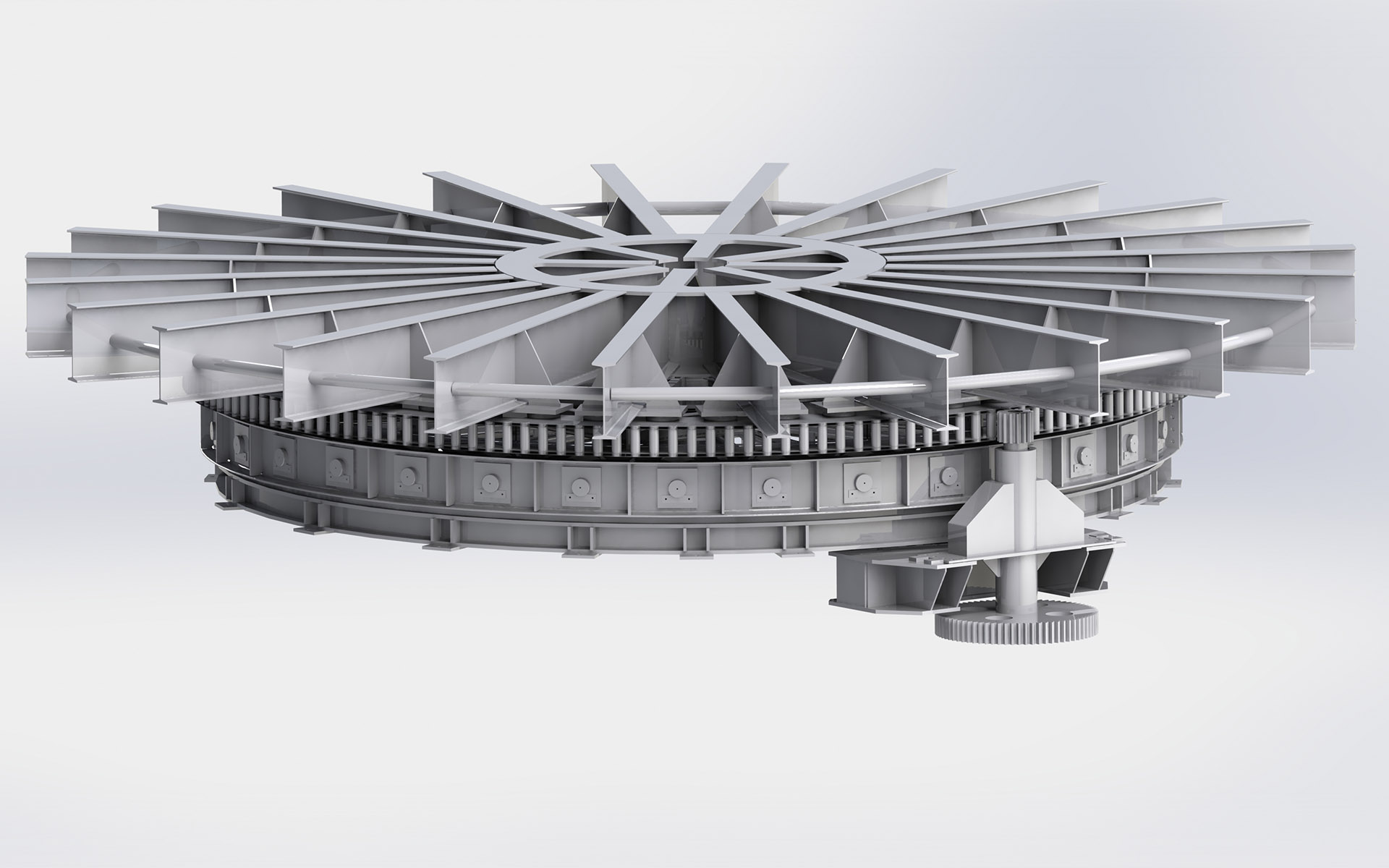

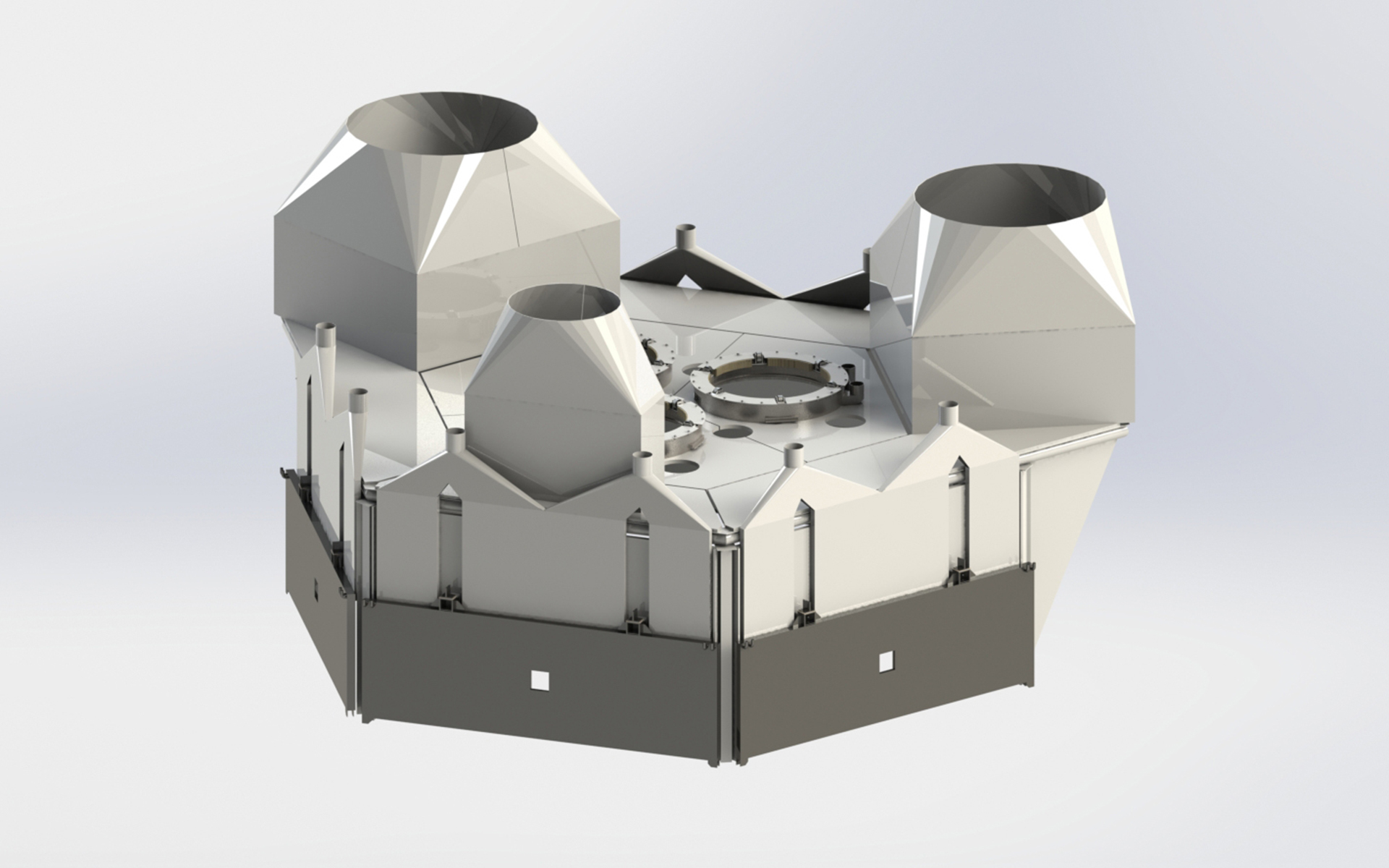

Furnace Rotating system

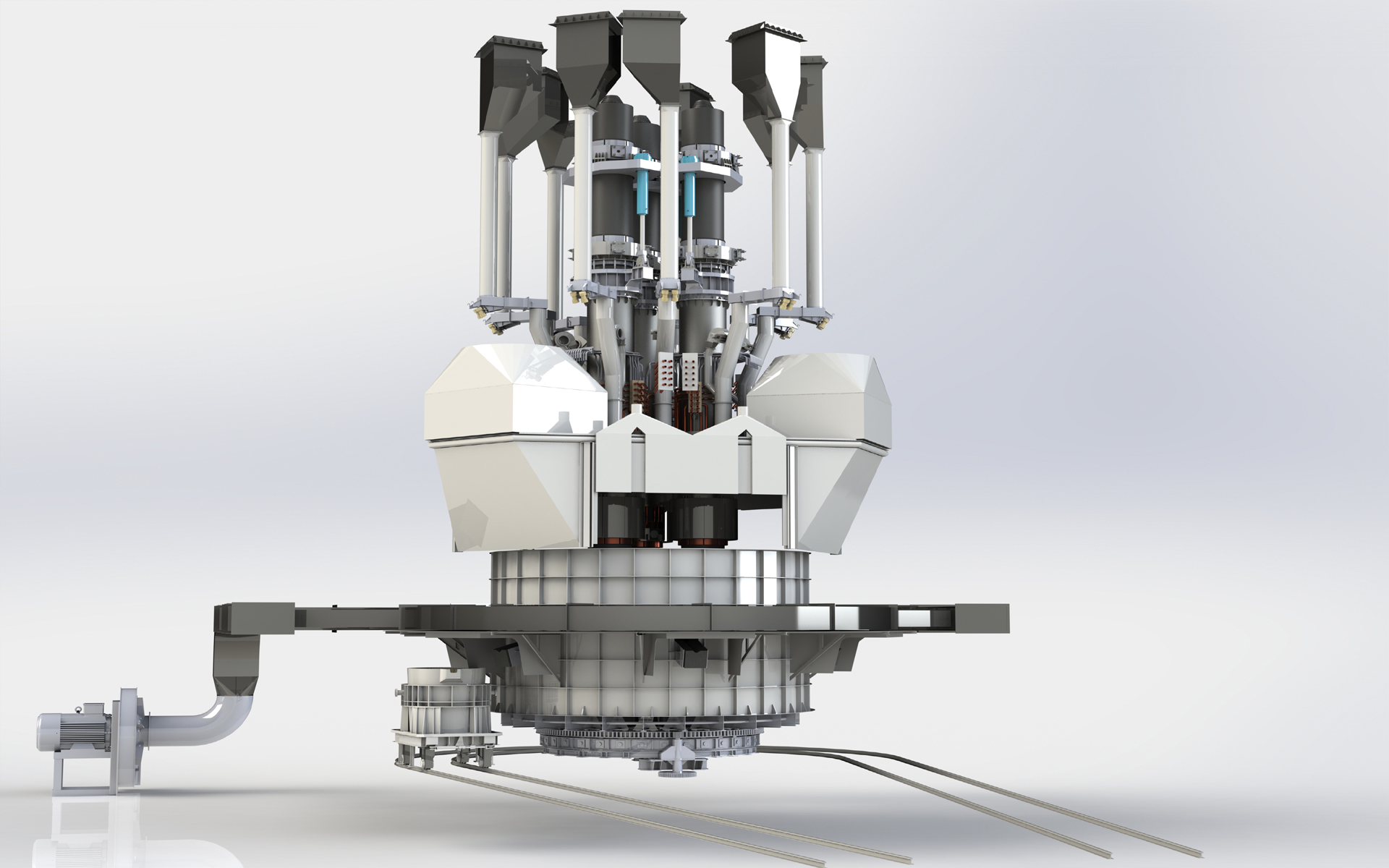

Furnace Assembly

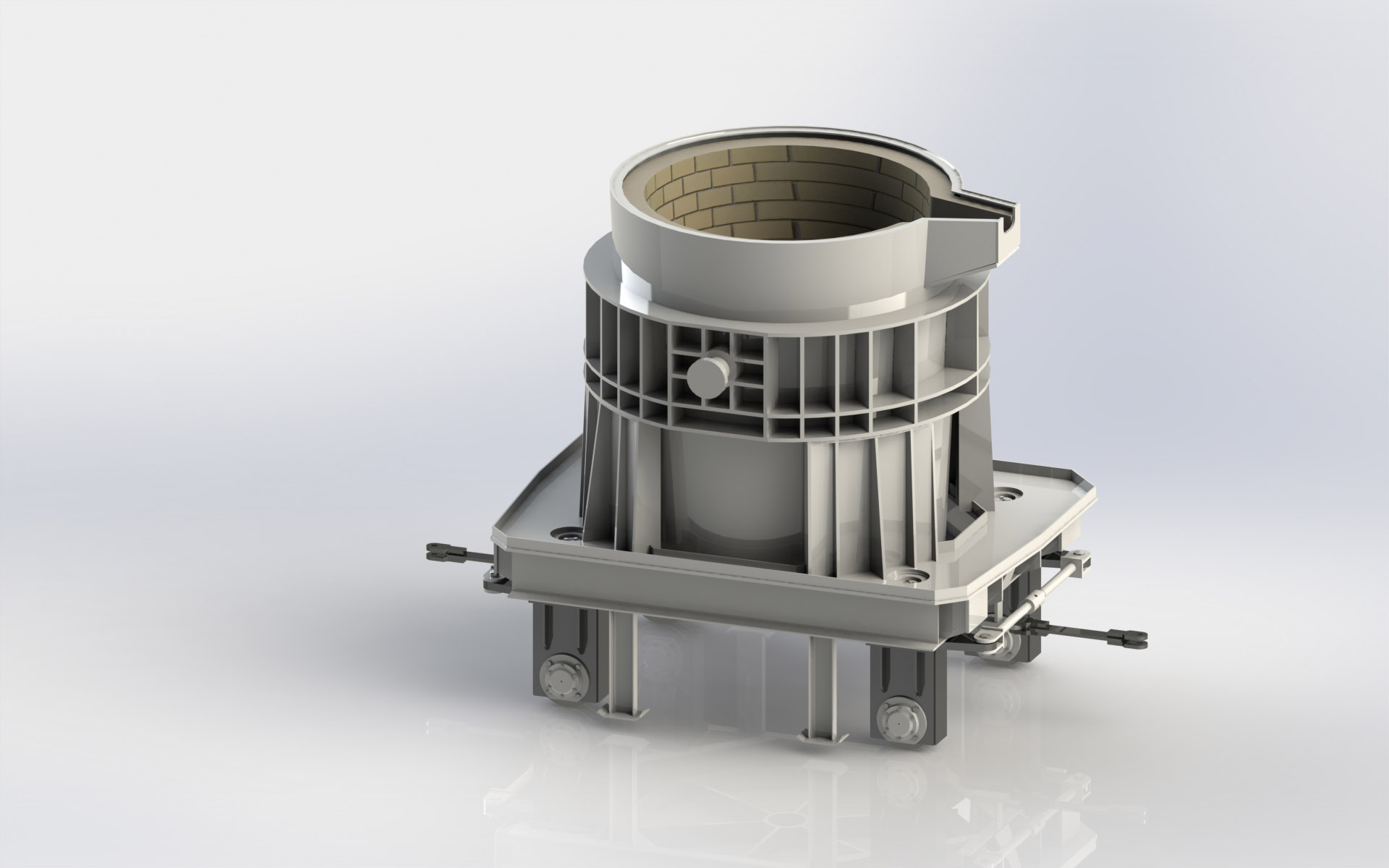

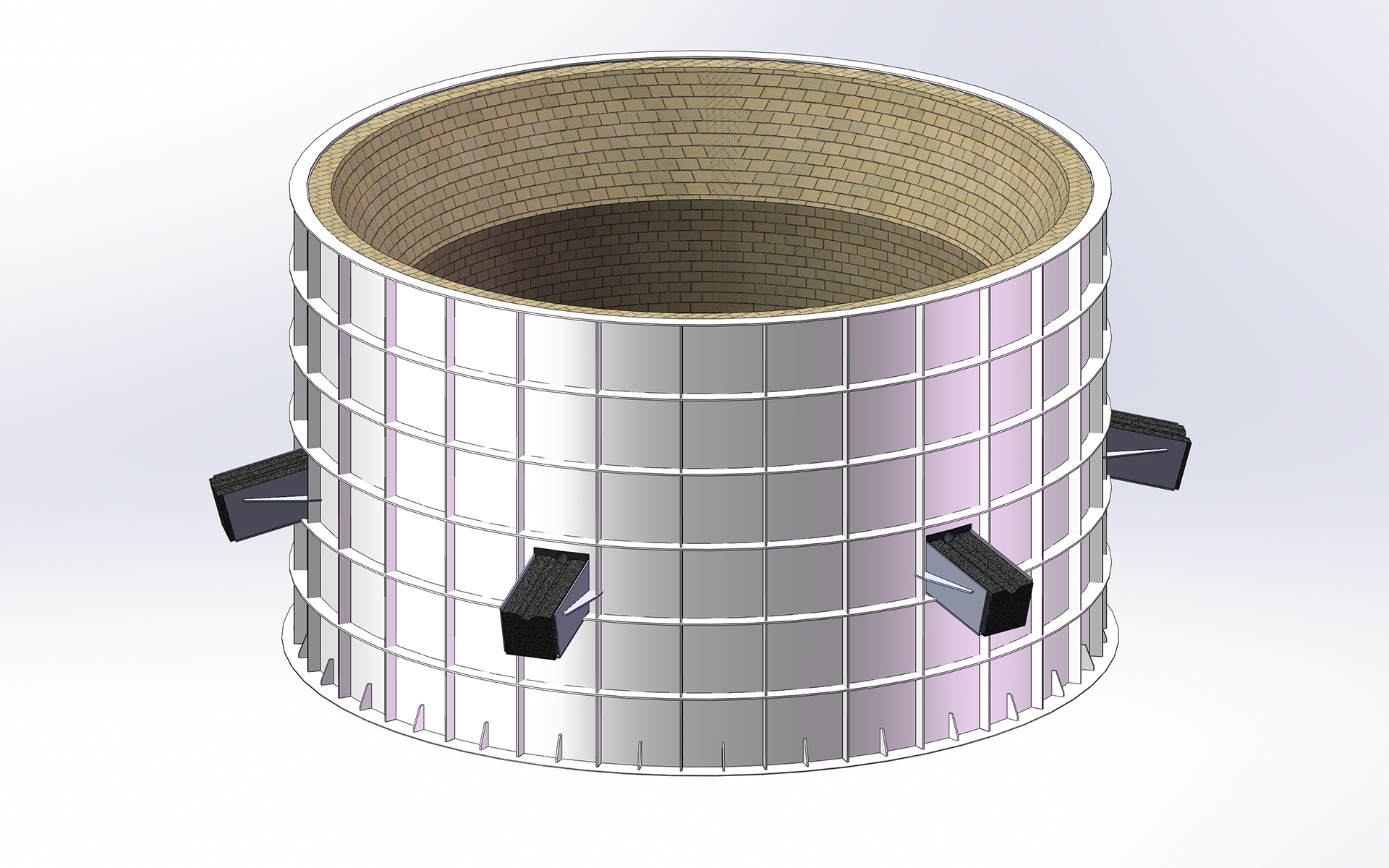

Furnace Shell

Upholding Brake

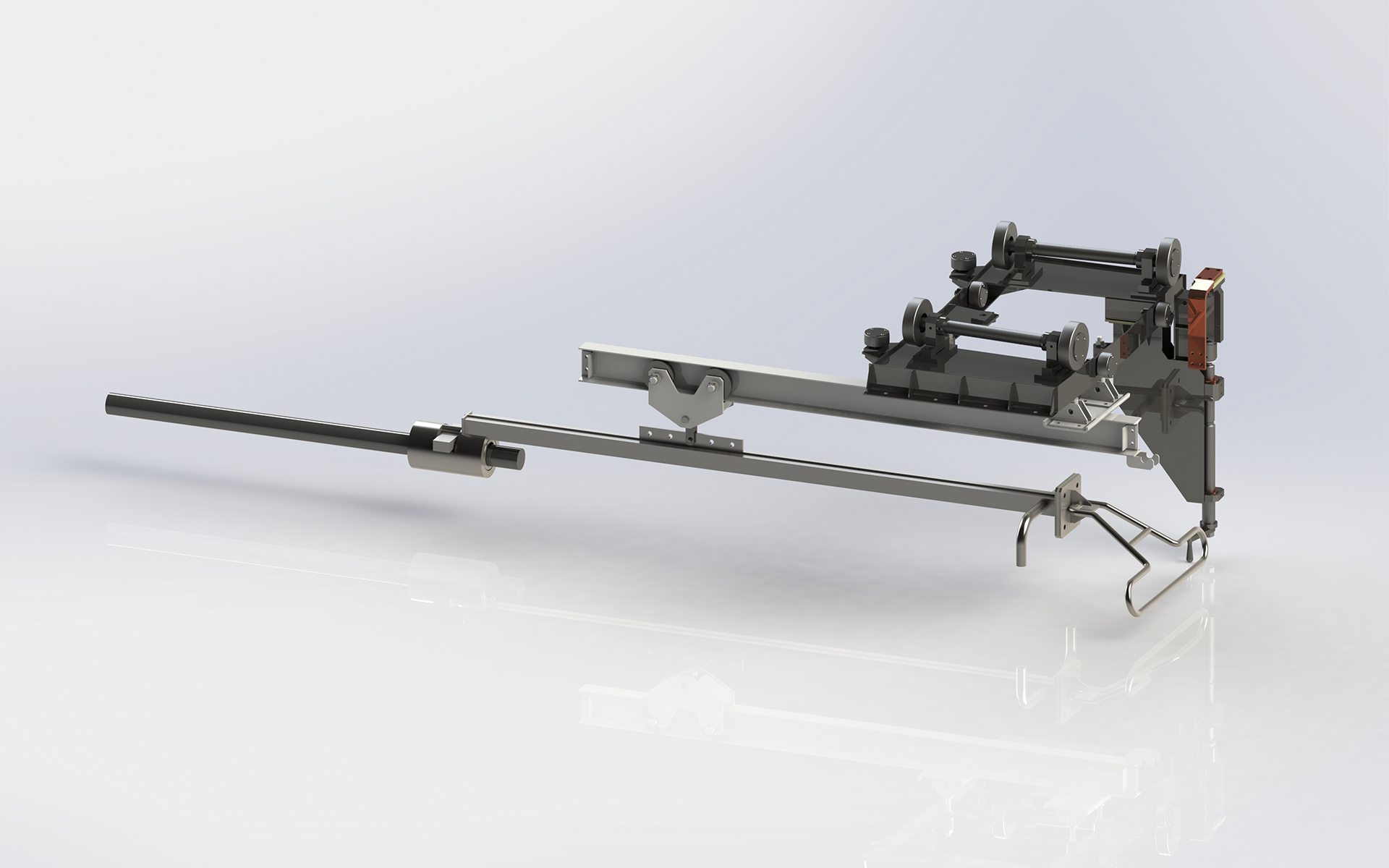

Moveable Arc Burner

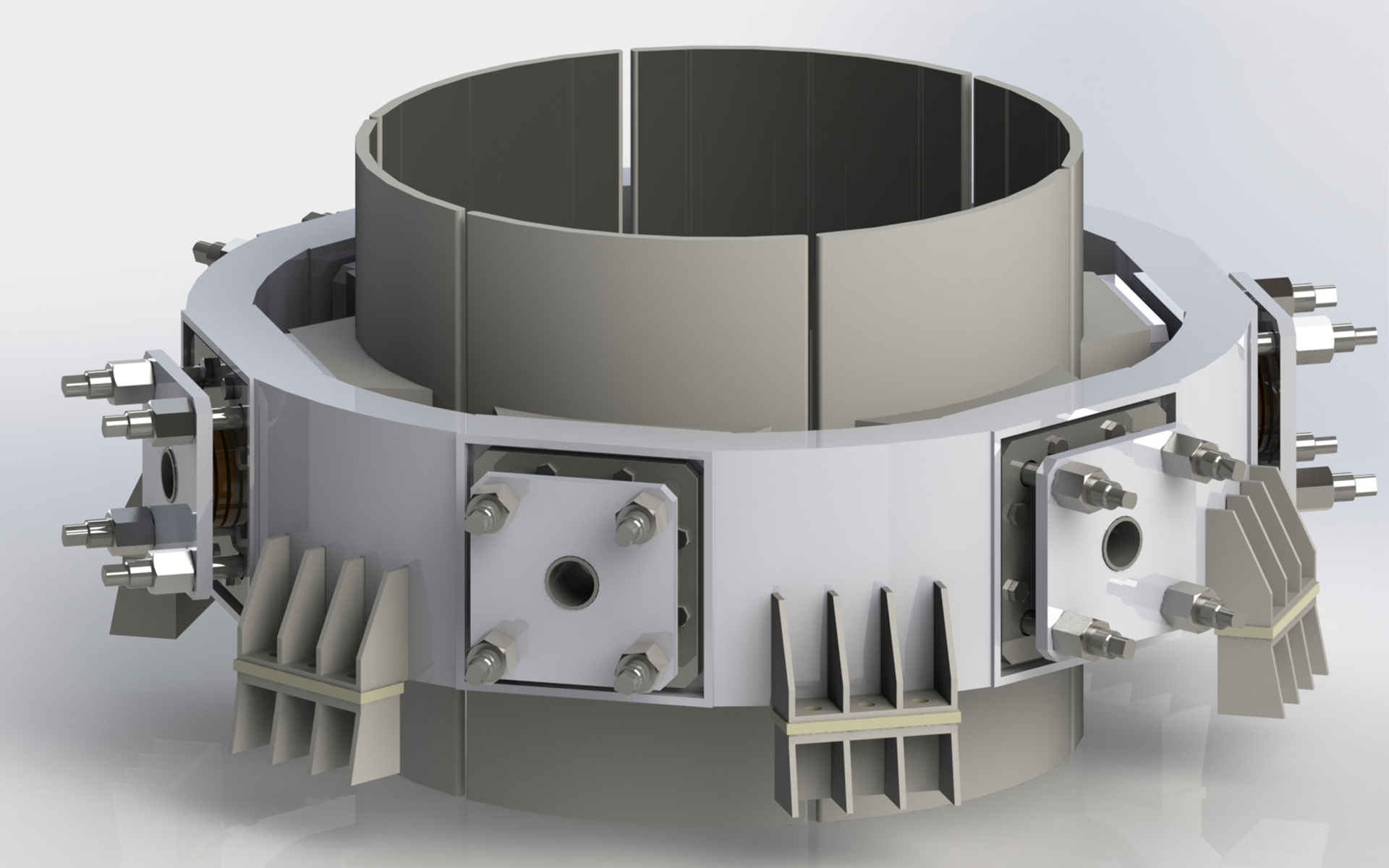

Pressure Ring

Short Net System

Smoke Hood