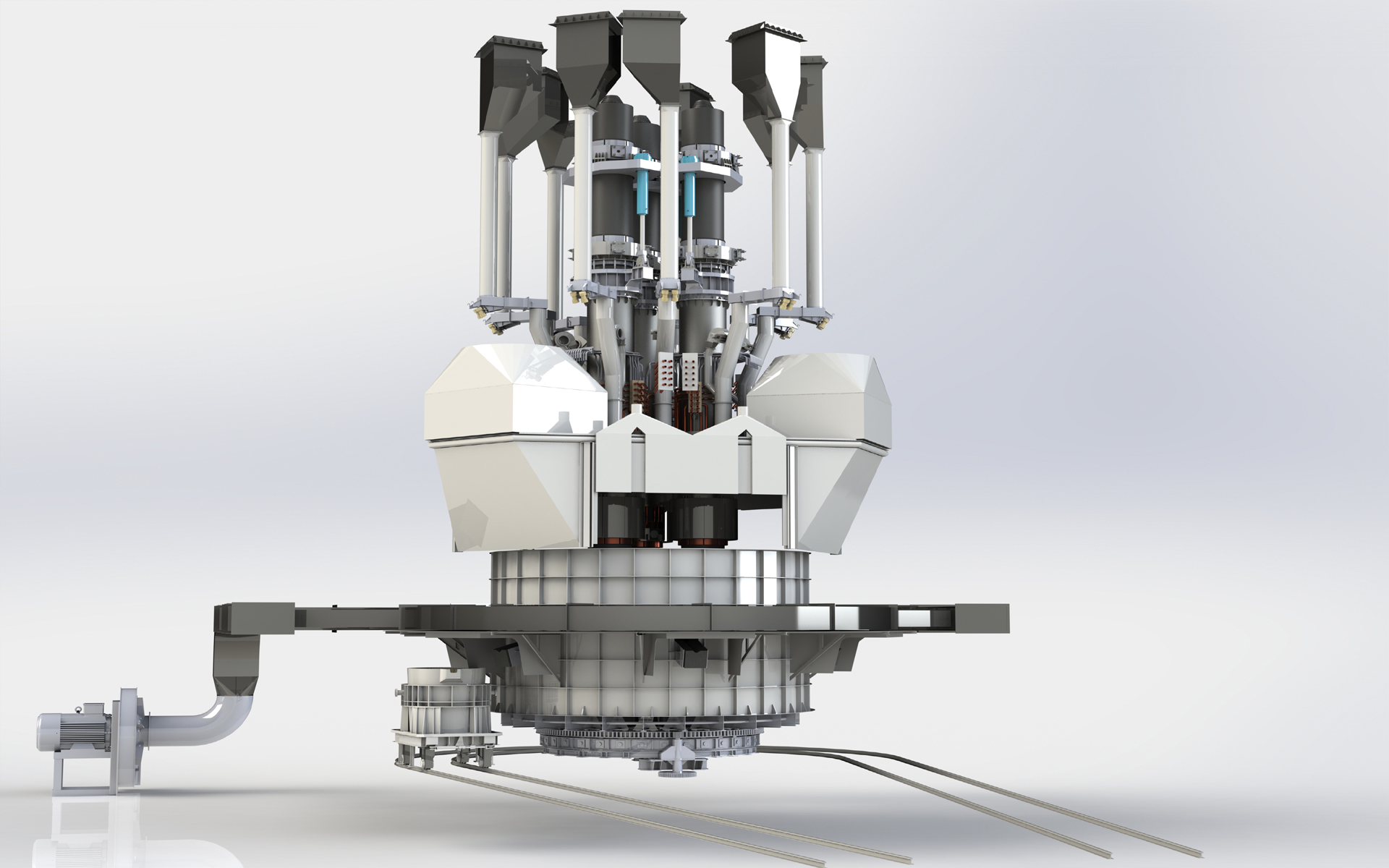

DC Electric Arc Furnace

DC Electric Arc Furnace

Product Description

DC Electric Arc Furnace refers to one phase electric arc furnace for steel melting with DC power.

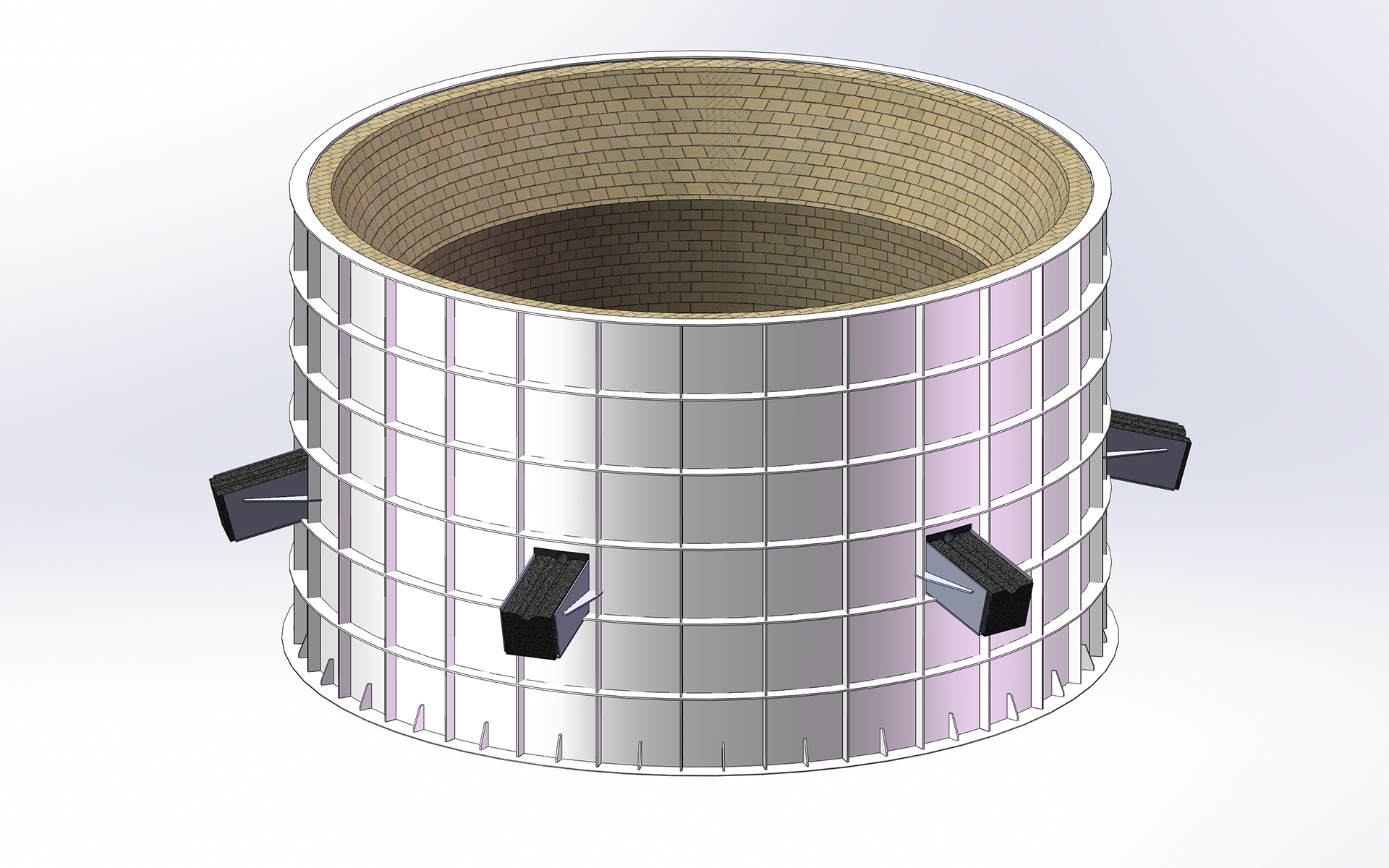

There is only one electrode above DC electric arc furnace, which is negative electrode and bottom electrode is positive electrode. Its power supply system is different from that of AC arc furnace. It is equipped with rectifier and reactor. The contact is installed on furnace bottom to form current circuit. Maintenance and service life of the contact are key problems in operation of DC arc furnace. Generally, copper plate is placed on furnace bottom steel plate to facilitate conduction. Three layers of magnesia carbon brick are built on copper plate, and then refractory is knotted on it.

DC Electric Arc Furnace compared with AC electric arc furnace, the main advantages of DC electric arc furnace are as follows:

(1) arc is stable and concentrated, molten pool is well stirred, temperature distribution in the furnace is uniform, and erosion of furnace lining is small;

(2) fluctuation of current and voltage is small, impact on power grid is reduced, and cable life is prolonged;

(3) electrode loss is less, 50% less than that of AC EAF. Performance of DC EAF is better than that of AC EAF, but it has been suffering from lack of high-power DC power supply, which has not been developed for a long time.

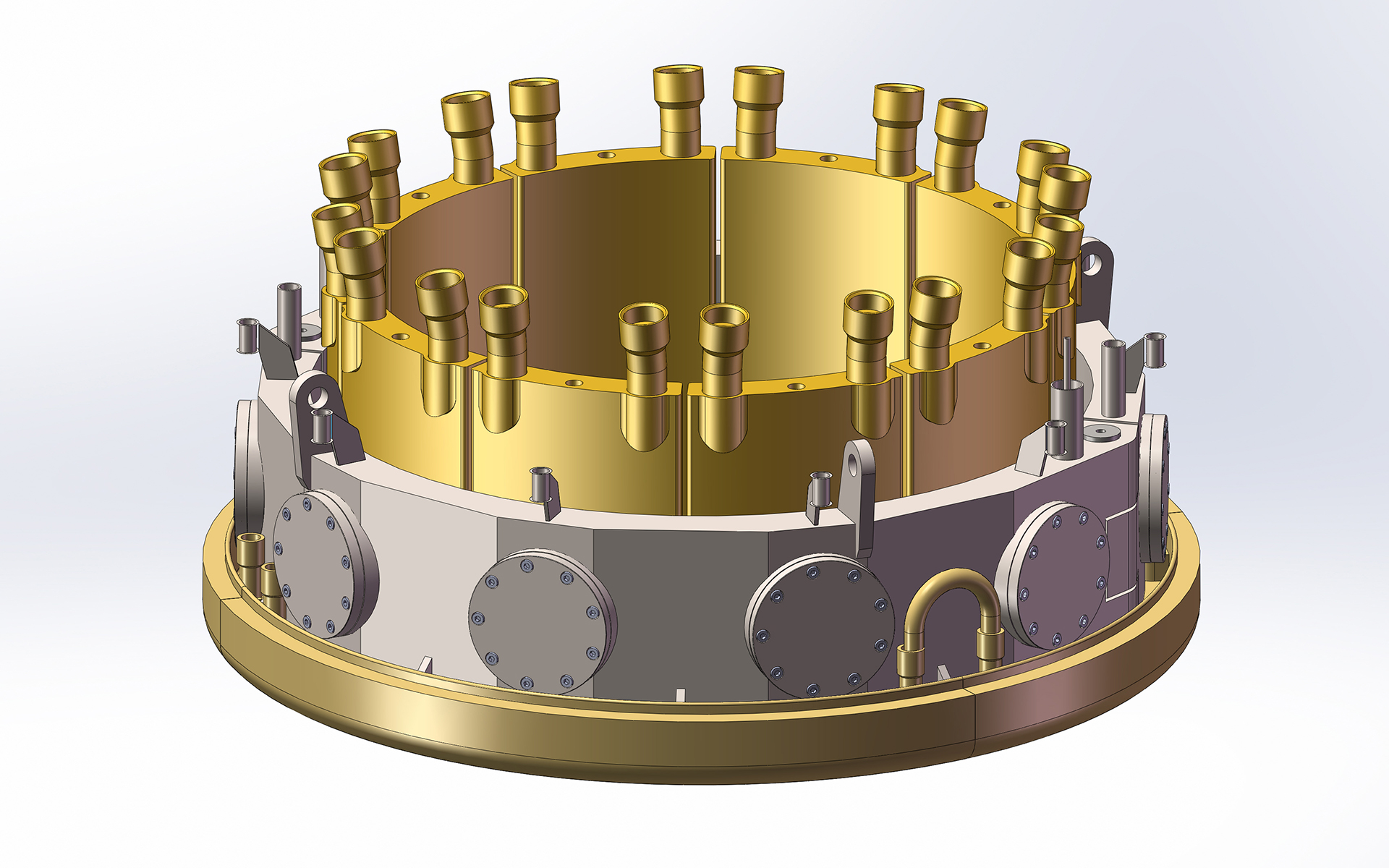

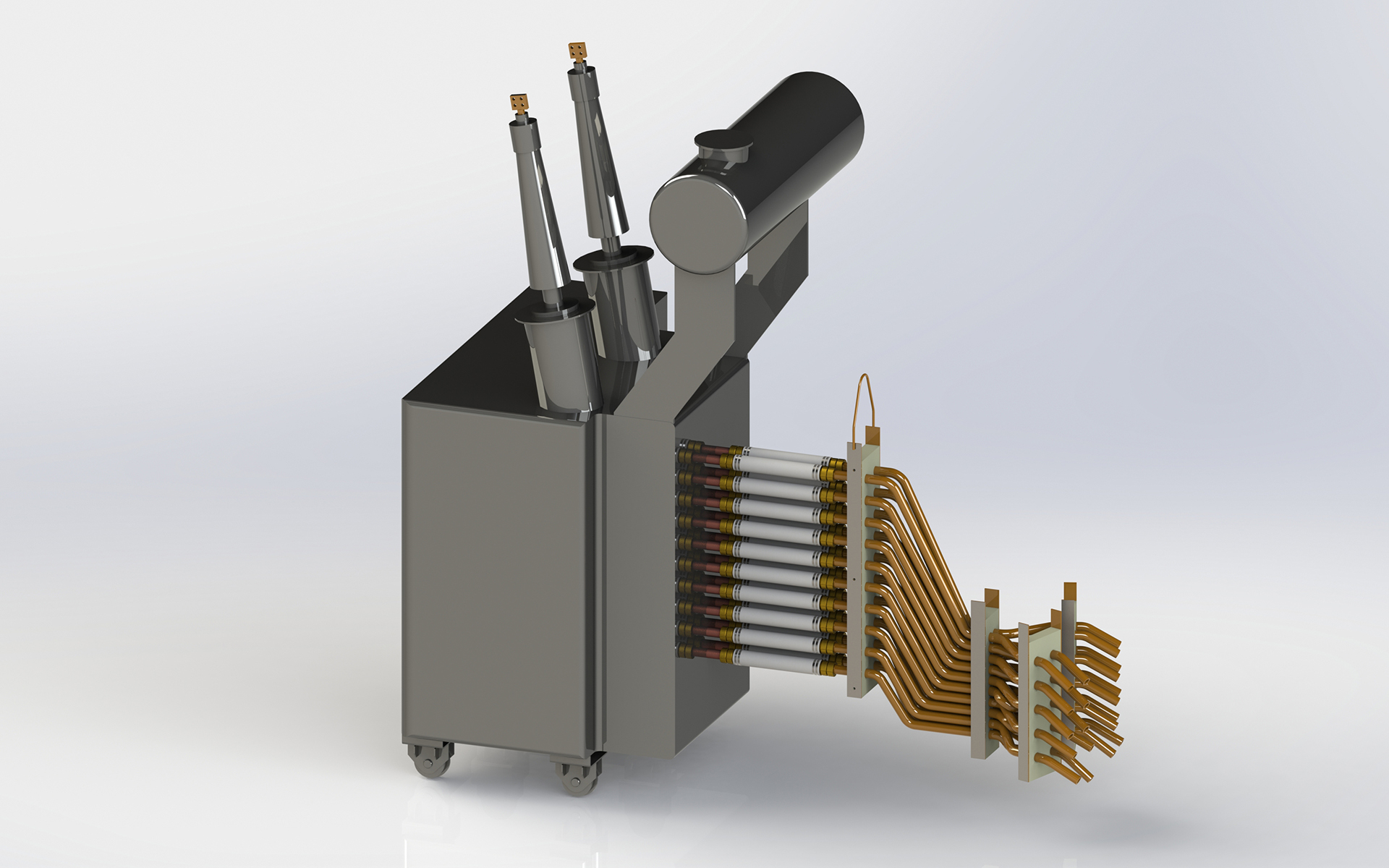

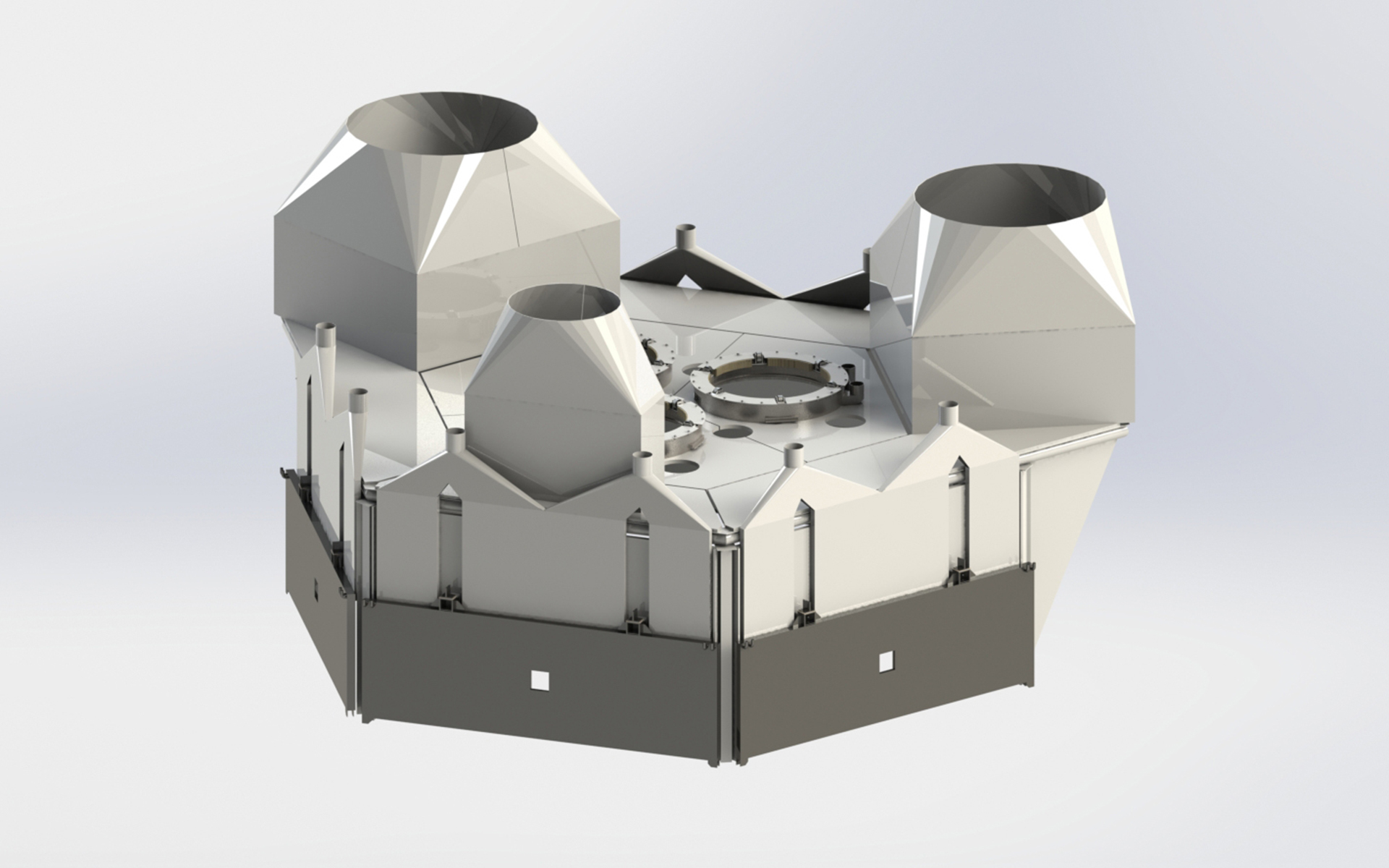

Parts Drawing

Copper Pipe Row

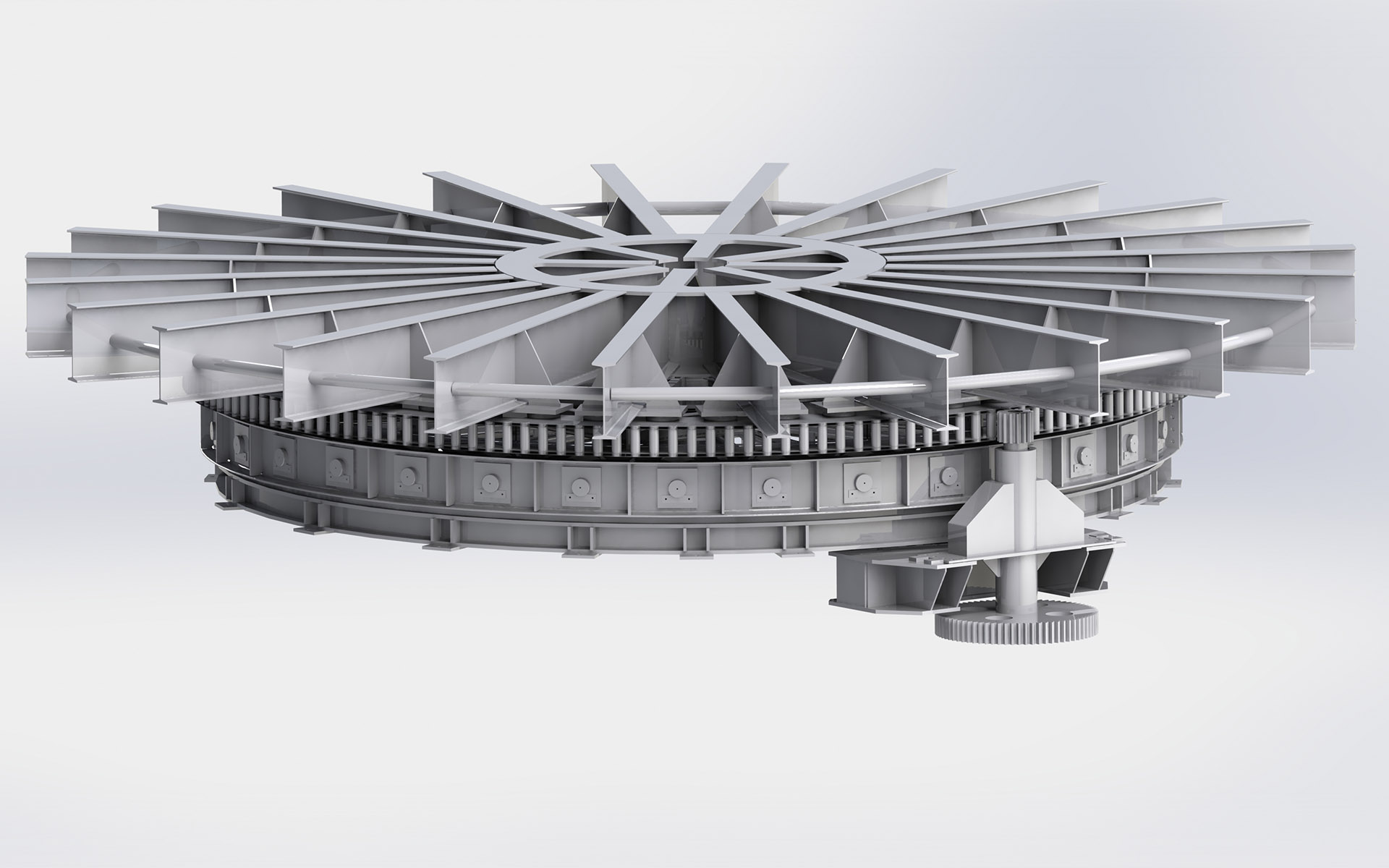

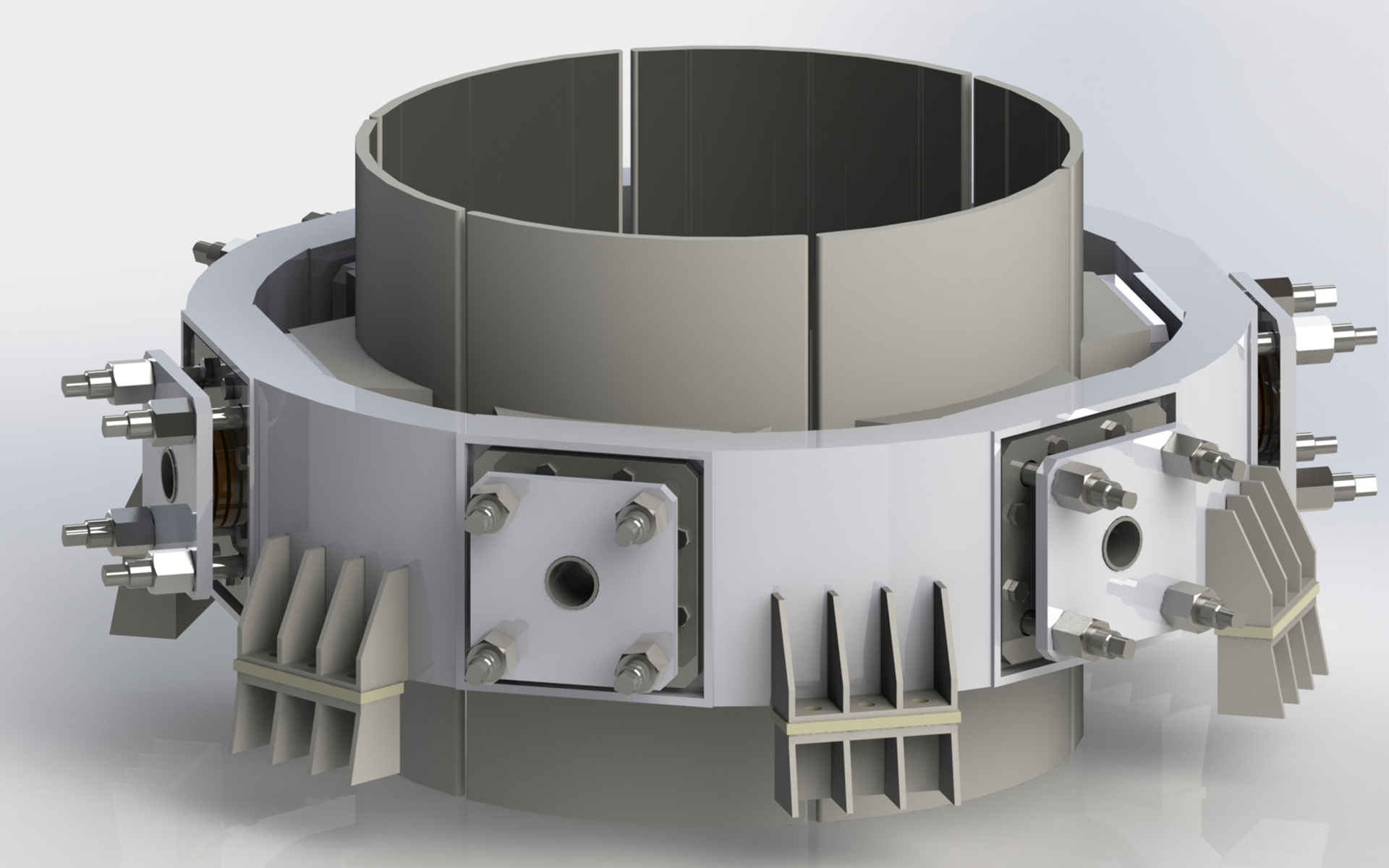

Furnace Rotating system

Furnace Assembly

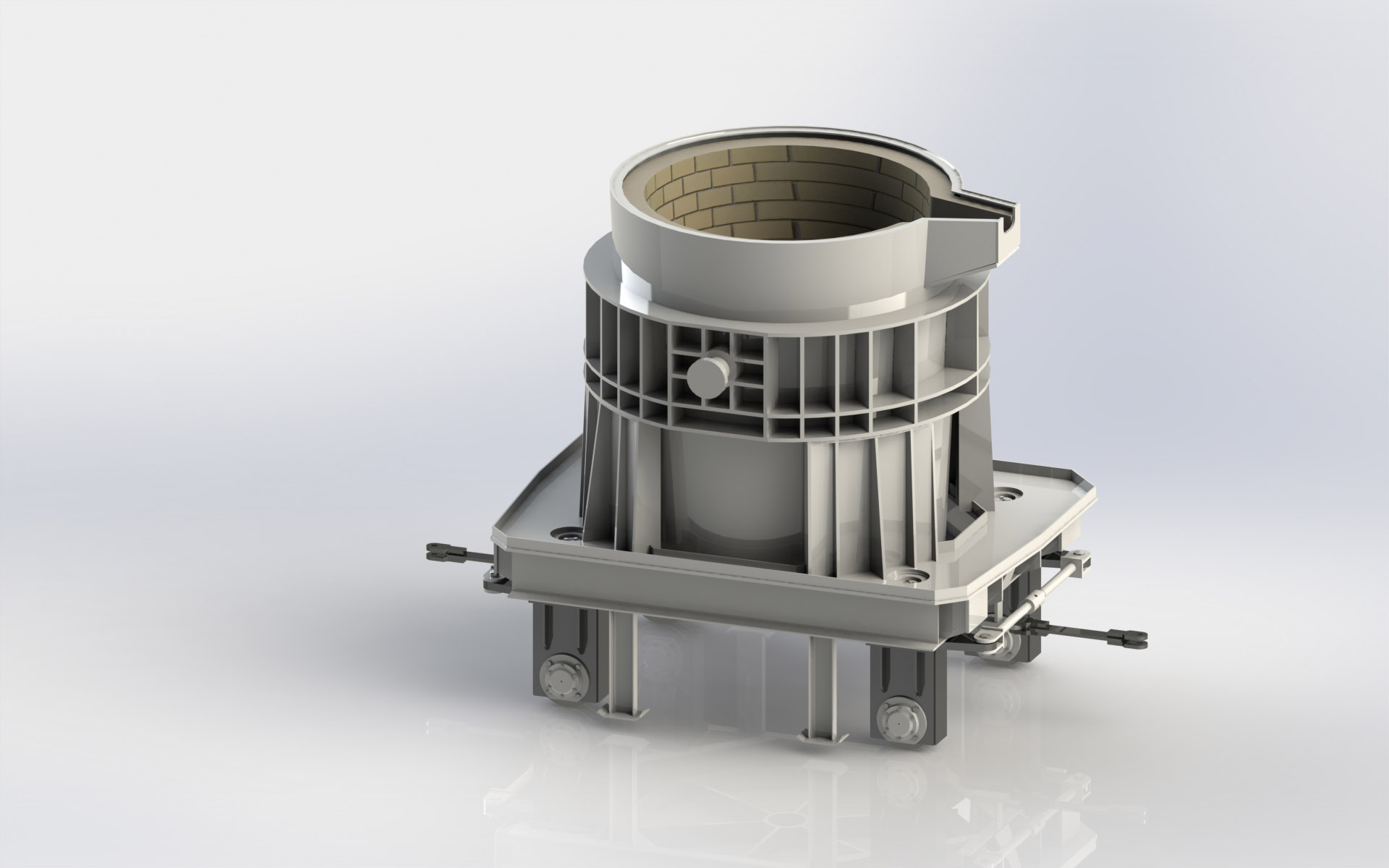

Furnace Shell

Upholding Brake

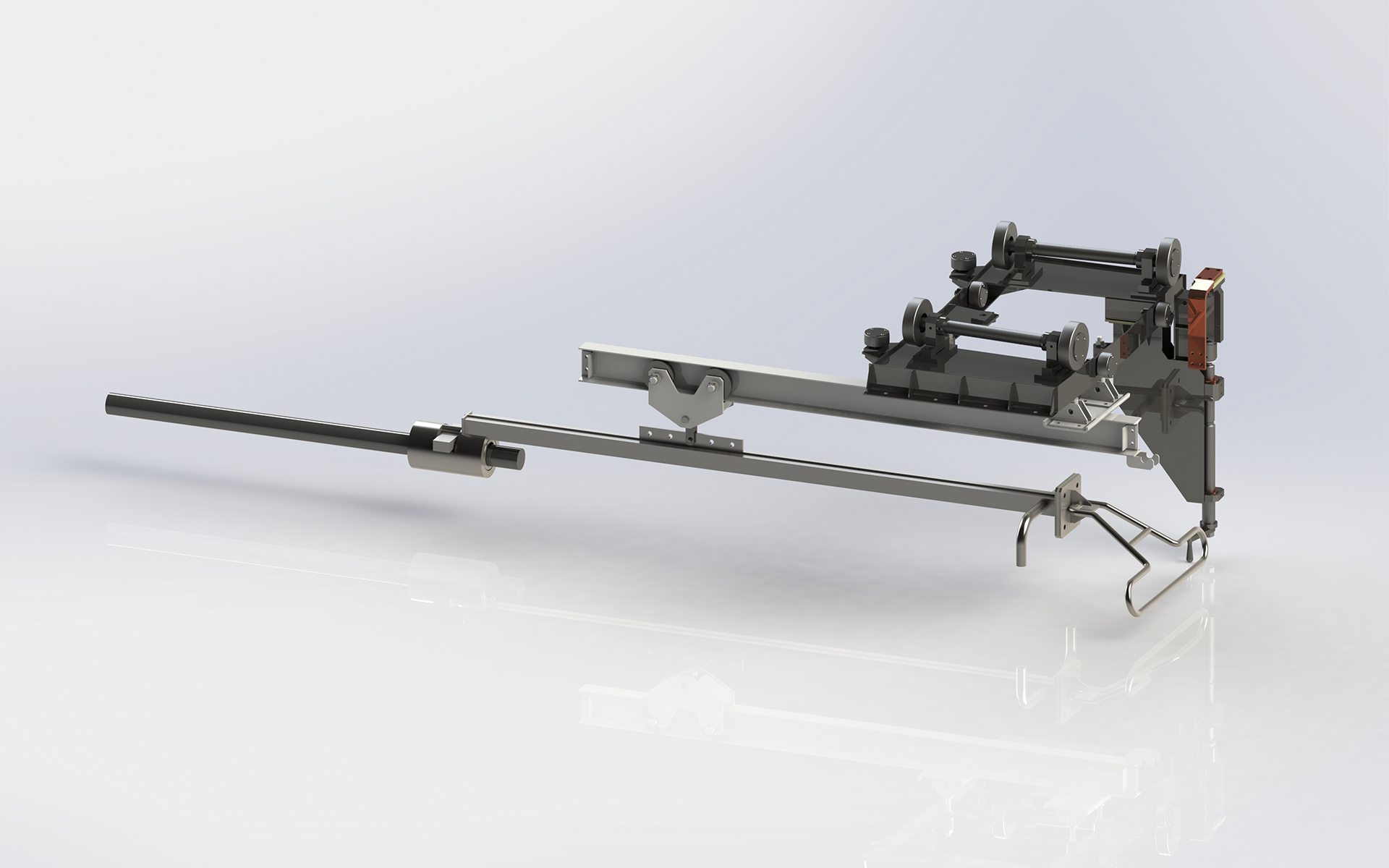

Moveable Arc Burner

Pressure Ring

Short Net System

Smoke Hood